Water scarcity has become a global debate. As such, the following quote is very apt: “The next war in the Middle East will be fought over water, not politics – 1985”.

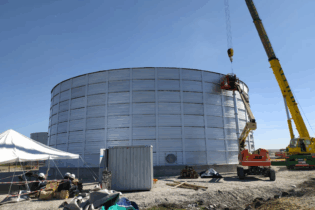

The same man was also quoted as saying: “Water will be more important than oil this century” – Former United Nations secretary general Boutros Boutros Ghali – 2003. Consequently, it is ironic that a petroleum company would play an integral part in providing the necessary investment which would see the construction of the largest salt water desalination plant in South Africa. The southern Cape town of Mossel Bay has been hard hit by recent scourges of drought. Consequently, the town’s water supply source has dropped to levels of 19%. As part of a bold, but necessary emergency measure, the construction of a R200 million salt water desalination plant was approved and set for construction in mid-June 2010. When completed, the plant will provide 15 million litres of desalinated water per day, of which 5 million litres will be allocated to co-sponsor PetroSA’s synthetic fuels plant in Mossel Bay. Along with the construction of the desalination plant, various pipeline infrastructure also had to be installed to facilitate the distribution of this new supply. Owing to the critical nature and stringent construction deadlines inherent in such a pioneering project, various innovative construction techniques were required to achieve these project outcomes. Owing to traffic flow volumes and latent settlement often associated with open-cut construction across roadways, it was clear that a more efficient and appropriate installation method was required. The close proximity of existing underground services also further compounded the issues associated with conventional open-cut construction. Fortunately, a trenchless installation alternative – which met and exceeded all the client’s criteria – was identified and approved as a feasible construction solution. The trenchless installation of pipelines has long been at the forefront of innovative and pioneering projects within the construction industry. The myriad of solutions available under the ambit of trenchless pipeline technology also affords engineers the opportunity to design for specific applications using the appropriate trenchless techniques, depending on design requirements. The pipeline route was established and a main contractor was appointed to install these pipelines using conventional open-cut techniques. Apart from the greenfields installations, various roads and railway lines also had to be traversed with this new pipeline. Horizontal directional drilling was selected as the trenchless method of choice for the road and rail crossings. The local roads authority required the new pressure pipelines to be installed within a sleeve wherever a road surface was being crossed. This meant that the 630 mm-diameter class 16 HDPE pipeline had to be housed within a larger 800 mm-diameter class 6 HDPE pipe. Specialist trenchless pipeline contractor, TT Innovations, was appointed to perform the various road and railway installations .The installation of both 800 mm-diameter pipes through a range of existing services provided for a challenging project. In the instance where the local railway line was crossed, the 630 mm-diameter class 16 HDPE pipe was installed directly underground, without the need for a larger-diameter sleeve pipe. A combined total length of 130 m of 630mm-diameter and 800 mm-diameter HDPE pipe was installed at three different locations. At the centre of this new pipeline installation lies the reconfiguration and reuse of the existing two reservoirs located close to the desalination plant. Both the 3.4 and 4 Mℓ reservoirs were allocated for use with this project.Instead of breaking down the existing structure to connect the new pipeline to the reservoirs, an innovative design team identified the potential for using trenchless techniques to mitigate costly and risky structural alterations to these reservoirs. Again, specialist trenchless pipeline contactor TT Innovations was approached and an innovative solution was devised.

Pipe ramming was identified as the most feasible installation method as this would allow for the installation of a large-diameter pipeline underneath the reinforced concrete wall of each reservoir without creating any voids around the installed pipe. When completed, two sections of 1 000 mm-diameter steel pipes would be installed underneath each of the reservoir floors, spanning from the perimeter of the reservoir wall and stopping on the inside of the reservoir storage area. Once installed, the soil from the inside of the steel pipe is removed and the product pipe is inserted.

This product pipe is later connected via a series of bends and fittings to the inside of the reservoir by a concrete chamber constructed on the floor of the reservoir. This will later serve as both the supply and drainage aperture.

With professional bodies like the South African Society for Trenchless Technology (SASTT), the applications and implementation of all forms of trenchless techniques – as well as their corresponding specialist contractors – becomes accessible to all engineering fraternities when technical solutions to complex construction problems are sought.

The conclusion of this critical project will highlight the ability and capacity of the local construction industry, in partnership with local government and the private sector, to provide innovative and class-leading infrastructure that benefits both the local community and its neighbouring petroleum company – literally turning oil (or the profits) into water.

by Neil van Rooyen

Author bio: Neil van Rooyen is a director at TT Innovations. He has worked previously at Martin & East (although it must be mentioned that TT Innovations is owned by Martin & East). Neil has a National Diploma in Civil Engineering as well as a B-Tech Degree in Urban Engineering – both from the Cape Peninsula University of Technology. One of his career highlights is TT Innovations winning a Southern African Society for Trenchless Technology (SASTT) Award of Excellence in 2008. Neil is a member of Consulting Engineers South Africa (CESA), Institute of Municipal Engineering Southern Africa (IMIESA) and the Water Institute of Southern Africa (WISA). He is also currently a board member of SASST.

When completed, two sections of 1 000 mm-diameter steel pipes would be installed underneath each of the reservoir floors, spanning from the perimeter of the reservoir wall and stopping on the inside of the reservoir storage area. Once installed, the soil from the inside of the steel pipe is removed and the product pipe is inserted.

This product pipe is later connected via a series of bends and fittings to the inside of the reservoir by a concrete chamber constructed on the floor of the reservoir. This will later serve as both the supply and drainage aperture.

With professional bodies like the South African Society for Trenchless Technology (SASTT), the applications and implementation of all forms of trenchless techniques – as well as their corresponding specialist contractors – becomes accessible to all engineering fraternities when technical solutions to complex construction problems are sought.

The conclusion of this critical project will highlight the ability and capacity of the local construction industry, in partnership with local government and the private sector, to provide innovative and class-leading infrastructure that benefits both the local community and its neighbouring petroleum company – literally turning oil (or the profits) into water.

by Neil van Rooyen

Author bio: Neil van Rooyen is a director at TT Innovations. He has worked previously at Martin & East (although it must be mentioned that TT Innovations is owned by Martin & East). Neil has a National Diploma in Civil Engineering as well as a B-Tech Degree in Urban Engineering – both from the Cape Peninsula University of Technology. One of his career highlights is TT Innovations winning a Southern African Society for Trenchless Technology (SASTT) Award of Excellence in 2008. Neil is a member of Consulting Engineers South Africa (CESA), Institute of Municipal Engineering Southern Africa (IMIESA) and the Water Institute of Southern Africa (WISA). He is also currently a board member of SASST.