Q. In the local water industry we have produced many unique solutions to meet rural and urban water delivery challenges. As a company, what are some of the challenges you have faced and the solutions you have found in response to these challenges?

A.To work in rural areas is quite a challenge; logistically speaking it’s a nightmare as building materials are usually of poor quality, very expensive and have a funny way of vanishing. These materials must most of the time be carted from afar and on bad roads. This leads to poor expensive concrete, thus poor products. Aquadam has identified this challenge and responded with the Muleby System tank (MST) a supply and install reservoir. These tanks are pre-casted in a controlled factory environment, with some of the best aggregates available. At 7 m high, panel it is not something that vanishes very easily. Installation takes a week, giving the main contractor more time to focus on the reticulation. This saves the client money that can assist him to build more needed reservoir, helping the country.

A.Aquadam builds reservoirs fast and effectively; all our products are good quality installed – saving money so more structures can be built, saving water for the ever growing water demand.

Storing water for the people – water is the most precious of our resources, and also the one that are the most neglected and wasted.

Q.As a proudly South African contractor or supplier to the water and civil infrastructure sectors, what have been some of the challenges experienced with local government?

A.In my limited personal experience, the clients are stuck in the old way of doing things, they are reluctant to change. I don’t know if it is lack of knowledge, it is quite difficult marketing new ways in the industry, or maybe it is just easy to copy and paste the old tried and tested way. I must say that this is starting to change; government is turning around – it wants to deliver.

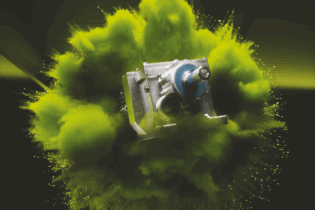

Then the need arrived for to erect mesh tank, the Budget tank, 8 mm welded mesh in a standard 3 m high galvanised panel, bolted together, really a tough customer.Then there is the Rolls Royce, the Muleby System tank. This pre-casted reinforced with pre-stressed cables sectional concrete tank is the ultimate. The slim design makes it very fast to erect and the combination of pre-stress panel that are horizontal post tension is very durable and a big money saver.