The anaerobic digestion method

by R Melamu*, A Lampard*, K Schafer* and H von Blottnitz* Waste paper can account for a considerable fraction of the municipal solid waste (MSW) stream. There is a limit to how much recycled fibre in paper can be used to make new products. Higher grade paper is generally preferred for recycling over low grade paper due to its longer fibres and higher market value. In South Africa, the fate of low grade waste paper that is economically non-recyclable typically is informal energy recovery or disposal with MSW to landfills, which is increasingly becoming a problem, due to dwindling landfill space in most cities. Where the disposal of non-recyclable paper involves open dumping or sanitary landfills, paper ultimately decomposes into the greenhouse gases (GHGs) methane and carbon dioxide, in a process called methanogenesis. Simultaneously, waste paper has some unutilised energy embedded in it that largely goes untapped. For the case of Cape Town, Nissing and Von Blottnitz (2007) estimated some 140 000 tpa (dry basis) of paper and another 105 000 tpa of wood fibre to be going to landfill– enough to provide up to 70% of the 10% renewable energy target the city set for itself. According to the waste management hierarchy, it should be environmentally beneficial to recover energy from non-recyclable paper rather than send it to a landfill. Biological technologies Anaerobic digestion :a natural process where bacteria breaks down organic matter into a biogas (a mixture of methane and carbon dioxide) in an oxygen free environment. This research explores how soggy and contaminated non-recyclable paper, such as sanitary paper, which is inappropriate for thermal treatment, behaves under anaerobic digestion conditions. Previous studies have explored anaerobic digestion of paper when co-digested with nitrogen rich sources, like algae (Yen and Brune, 2007), while a study by Wang (1999) identified hydrolysis of the cellulose strands to glucose as the rate-limiting step in the anaerobic digestion of paper. There have been studies that have specifically explored the effect of pre-treatment of paper sludge from the pulp and paper industry on residence time in the bio-digester and methane recovery (Elliott and Mahmood, 2007). However, the focus has been mainly on one type of non-recyclable paper (paper sludge) and with just one chemical pre-treatment method (alkaline pre-treatment). In this paper, both chemical and biological pre-treatment methods are investigated on four types of paper, three of which can be classified as non-recyclable. Acid and alkaline pre-treatment methods are explored on the chemical pre-treatment front, while enzymatic treatment is looked into for biological pre-treatment methods. Materials and methods Materials The following paper grades were subjected to the three pre-treatment methods (acid, alkaline and enzymatic) and later underwent anaerobic digestion: toilet paper (TP), cardboard (card), waxed paper (WP), and printing paper (PP). These paper grades were collected as clean samples that had not undergone any natural degradation, which would have taken place if the paper samples had been collected from waste paper storage or a landfill. The inoculum used came from two different sources, one from South African Breweries and the other from a sewagesludge digestion unit, these constituted a mixture of fermentation bacteria required for anaerobic digestion. A study by Yunqin (2009) found that feed-to-inoculum molar ratio of 1:1.5 yielded high methane percentages in the anaerobic digestion of pulp and paper sludge, and this ratio was used. Methods The pre-treatment technologies used on the paper grades listed above and anaerobic digestion experimental set-up are presented in this section. Acid pre-treatment Acid catalysed hydrolysis to form glucose may take place using concentrated sulphuric acid or dilute sulphuric acid; when using concentrated sulphuric acid glucose needs to be separated from the acid solution using column chromatography (Speight, 2008), for this reason the paper samples presented in this project were pre-treated using dilute sulphuric acid. This method entails random breaking of the polymer in paper at random points, reducing it to simpler sugars. In this experiment paper samples were treated with 12% v/v solution sulphuric acid. The paper samples were weighed out and 4.8 g of each sample were added to 250 ml of acid solution. The solution was blended and heated to 1250C in an autoclave for four hours. The resulting solution was then neutralised using sodium hydroxide and 60 ml of a homogenous solution was used as a feed to an anaerobic digester. Alkaline pre-treatment In an alkali pre-treatment method glucose units are released in isolation from the cellulose molecule, resulting in a depolymerisation reaction known as the peeling-off, this reaction occurs if β-elimination occurs at the C-4 carbon atom, one hexose monomer unit is split off from the cellulose molecule, and the next glucose end group can take part in the reactions (Pavasars, 2003). In this pre-treatment method, a prepared 10 wt% percentage sodium hydroxide solution was added to the 4.8 g paper sample. The samples were constantly stirred for 6 hours at 370C to ensure even dispersion of sodium hydroxide. The paper mixture was then neutralised to a pH of 6-7 with sulphuric acid, and a 60 ml homogenous solution was then fed into bio-digester. Enzymatic pre-treatment Cellulases are a group of enzymes that are used to catalyse cellulosic materials into simpler sugars, for example, glucose. In this study, two different enzymes were used, one cellulase from Trichoderma Viride (Enzyme A) and the other cellulase from Aspergillus Niger (Enzyme B). Three different runs were carried out, two with each enzyme and a third one which was a mixture of both enzymes. Enzymes were mixed at a ratio of 1:1 as suggested by Van Wyk (1997) for a mixture enzyme. The experiments for individual enzymes were carried out singularly, while for the enzyme mixture was carried out in duplicate. Experimental set-up Sterile Pyrex bottles sealed with rubber stoppers and aluminium crimps were used as the anaerobic batch reactors, each with a capacity of 125 ml; nitrogen gas was used to sparge the bottles to create anaerobic conditions. A water bath was used to maintain the temperature of the anaerobic digester at 37 0C.The displacement method using a measuring cylinder immersed in a water basin connected to a syringe with a plastic tube was used to measure resultant gas. Food colourant was used in the water basin for ease in reading off gas produced; pH was also monitored with a pH probe. Two inoculums control samples were set up to determine whether the inoculums produced any gas. The last control sample was made up of glucose with approximately an equivalent mass to cellulose in paper samples. The bio-digester reactors components comprised paper suspension, the inoculum, water and medium with trace elements essential for bacteria in the inoculum to feed on, as adopted from a study by Angelidakia (2004).Gas chromatography was performed on anaerobic digestion produced biogas from paper samples to determine methane content in the biogas. Results In this section, results from pre-treatment and bio-methane potential (BMP) are presented.

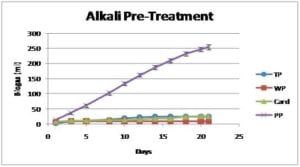

Figure 1: Comparison of paper types pre-treated with sodium hydroxide

It can be observed that PP outperforms the non-recyclable papers by far. The other three paper types’ biogas production appears to plateau, while that of PP appears to be increasing over the 20 days of anaerobic digestion.

Figure 2: Comparison of paper-types pre-treated with sulphuric acid

The methane production for all samples was limited. All the samples display similar reaction kinetics as can be observed with the shapes of the curve which increases rapidly in the first 3 days after which a 10 day lag period is observed followed by an increase.

Figure 3: Comparison of paper types with enzyme A

Figure 4: Comparison of paper types with enzyme B

Figure 5: Comparison of paper types with a mixture of enzymes A and B

PP produced the most biogas for all the enzyme pre-treatment methods on the four paper types under investigation. PP biogas production was still increasing at the end of 20 days under which the anaerobic digestion was undertaken whereas that of WP had tailed off after six days. Figure 6: Percentage methane in the biogas produced from paper samples

It can be observed from Figure 6 above that biogas from PP had the highest percentage of methane for all the pre-treatment methods while WP and TP generally had the lowest.

Discussions

Using the amount of biogas produced for paper samples investigated as a determinant of the pre-treatment method effectiveness, enzymatic pre-treatment generally emerged superior over the chemical pre-treatment methods. It can be observed that for individual enzymes and a mixture of enzymes each paper sample produced more biogas than in the alkali and acid pre-treatments. This could possibly be attributed to the fact that it is more difficult to control pH in chemical pre-treatment methods than in enzymatic ones.

Of the paper samples investigated, PP emerged superior in all the pre-treatment methods producing up to 250 mℓ of biogas except in acid pre-treatment where, like all the grades, no methane was produced. This superior performance of PP probably is due to it containing a filling material which can be either kaolin clay orcalcium carbonate, usually used for brightness and better printability. This is thought to help maintain the pH at optimal range where the methane producing bacteria thrives.

Generally a mixture of enzymes gave better biogas yields than individual enzymes, while enzyme A seemed to also give better yields than enzyme B. This can indicate that different enzymes are selective to the different components in the paper samples.

Conclusions

The aim of this research was to explore how non-recyclable paper behaves under anaerobic digestion conditions. Since one of the rate-limiting steps in anaerobic digestion has been identified to be hydrolysis of cellulosic material into monosaccharides, this study endeavoured to investigate how different pre-treatment methods affect biogas production in anaerobic digestion.

The most effective pre-treatment method of the types investigated was found to be enzymatic. The modest performances of the two chemical methods in comparison with enzymatic could be attributed to the fact that they were more prone to result in pH values outside the optimal range, which would have interfered with proper functioning of bacteria during anaerobic digestion. Better pH control and inoculation is envisaged to yield better results. PP generally responded the best to all pre-treatment methods; this could be linked to the presence of kaolin or limestone which is thought to provide a buffering effect during anaerobic digestion.

Although this study points to the potential of recovering energy from non-recyclable paper, the results should be interpreted with caution as this was an exploratory study that is undergoing refinement in the same research group. Also, investigations into which biological conversion technology will best recover energy from non-recyclable paper between fermentation into ethanol and anaerobic digestion into biogas are also being pursued.

ACKNOWLEDGEMENTS

The authors would like to acknowledge Eskom Tertiary Education Support Programme (TESP) for funding the E&PSE group at University of Cape Town in support of evaluating options for energy recovery from waste paper.

*Chemical Engineering, University of Cape Town

Figure 6: Percentage methane in the biogas produced from paper samples

It can be observed from Figure 6 above that biogas from PP had the highest percentage of methane for all the pre-treatment methods while WP and TP generally had the lowest.

Discussions

Using the amount of biogas produced for paper samples investigated as a determinant of the pre-treatment method effectiveness, enzymatic pre-treatment generally emerged superior over the chemical pre-treatment methods. It can be observed that for individual enzymes and a mixture of enzymes each paper sample produced more biogas than in the alkali and acid pre-treatments. This could possibly be attributed to the fact that it is more difficult to control pH in chemical pre-treatment methods than in enzymatic ones.

Of the paper samples investigated, PP emerged superior in all the pre-treatment methods producing up to 250 mℓ of biogas except in acid pre-treatment where, like all the grades, no methane was produced. This superior performance of PP probably is due to it containing a filling material which can be either kaolin clay orcalcium carbonate, usually used for brightness and better printability. This is thought to help maintain the pH at optimal range where the methane producing bacteria thrives.

Generally a mixture of enzymes gave better biogas yields than individual enzymes, while enzyme A seemed to also give better yields than enzyme B. This can indicate that different enzymes are selective to the different components in the paper samples.

Conclusions

The aim of this research was to explore how non-recyclable paper behaves under anaerobic digestion conditions. Since one of the rate-limiting steps in anaerobic digestion has been identified to be hydrolysis of cellulosic material into monosaccharides, this study endeavoured to investigate how different pre-treatment methods affect biogas production in anaerobic digestion.

The most effective pre-treatment method of the types investigated was found to be enzymatic. The modest performances of the two chemical methods in comparison with enzymatic could be attributed to the fact that they were more prone to result in pH values outside the optimal range, which would have interfered with proper functioning of bacteria during anaerobic digestion. Better pH control and inoculation is envisaged to yield better results. PP generally responded the best to all pre-treatment methods; this could be linked to the presence of kaolin or limestone which is thought to provide a buffering effect during anaerobic digestion.

Although this study points to the potential of recovering energy from non-recyclable paper, the results should be interpreted with caution as this was an exploratory study that is undergoing refinement in the same research group. Also, investigations into which biological conversion technology will best recover energy from non-recyclable paper between fermentation into ethanol and anaerobic digestion into biogas are also being pursued.

ACKNOWLEDGEMENTS

The authors would like to acknowledge Eskom Tertiary Education Support Programme (TESP) for funding the E&PSE group at University of Cape Town in support of evaluating options for energy recovery from waste paper.

*Chemical Engineering, University of Cape Town