Corestruc designs, manufactures and constructs precast concrete structures that are ideally suited to the infrastructure delivery construction industry. Richard Jansen van Vuuren speaks to Willie de Jager about the company and its products.

Please provide a brief background to Corestruc Corestruc is part of a group of companies whose main business was initially property development, building and civil construction. As developers and contractors we realised that constructing structures in precast concrete instead of the conventional methods saved time on projects and created savings on direct cost because of the use of more technologically advanced methods. Two years of research was done before the concept was finalised. Most of this research was done in Europe where Tian de Jager spent 90% of his time conducting research in Europe. What is the core function of the business? Corestruc‘s main business is the design, manufacturing and construction of precast concrete structures in South Africa and neighbouring countries. Typical projects are reservoirs, water treatment works, sewerage works, sports stadiums, bridges, office blocks, industrial warehouses, shopping centre’s etc. Please give an outline of your installation capabilities Corestruc focuses on the total solution in terms of design manufacturing and installation. An important part of the installation is proper contract management of the project. We try to anticipate from experience where precast will influence the project beforehand and coordinate and program/plan accordingly with the main contractor to ensure that the advantages of precast are used to its full potential. The installation teams consist of experienced site agents and rigging supervisors ensuring quick installations times without unexpected surprises. Our standard operating procedures are also well documented and new employees well trained. Please highlight a few projects that Corestruc has supplied projects and services to supplying the project names and a brief description work for each project as well

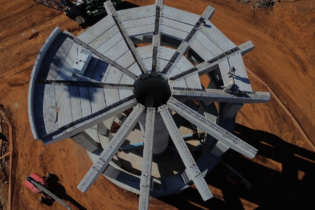

- 50 ML Krugersburg (Polokwane) Reservoir and 45 ML Longridge (Bloemfontein) Reservoir

- Precast beams and bridge barriers for the Polokwane Municipality

- Honda showroom – The total structure was pre-casted with various precast elements ranging between square and bull nose columns, square T and I beams, rectangular crash barriers and 150mm – 250mm deep hollow core slabs. The quality of the off shutter finish of the structure prompted the client to omit the paint finish specified. We omitted 38 columns from the insitu design because of the cost effective use of pre-stress enabling longer spans.

- University of the North lecture halls – where we used our 320 mm deep hollow core slab on a three storey building with a clear span of 13 m with a live load of 5 KN per m2.