What role do pipes, pumps and valves play in infrastructure?

AA A very important role in the larger infrastructure arena, as the demand for water and sewage transfer is highly important due to the large quantity thereof. Without pipes and valves one cannot direct and control the medium, and without pumps, one cannot move the medium.

All the older models of pumps that are installed and operating today are still running at low efficiencies, which results in the energy usage being very high. This is a big problem due to the energy supply being under pressure in our country. How important is identifying the right product “fit” for the project?

Very important because the wrong product in a project will have a major impact on your energy costs and maintenance, as well as on the pipes and valves, and can cause damage to the equipment installed. How much impact does using the right product have on water loss?

Fortunately with a pump, water loss can only occur when there is a leakage on the pump itself. Making sure all the seal ratings are correct when selecting a pump for a certain project is therefore critical. How important are regular inspections in ensuring effectiveness?

Each part on a pump has a lifespan, so regular inspections ensure all faulty parts are detected and replaced; this will ensure your pump is running at the best efficiency at all times and that the operating costs are low at all times. What are the newest offerings your organisation has for the market?

All our products are high quality and affordable, and offer cost-saving solutions.

Why are your products uniquely suited to local conditions?

Due to South Africa’s energy supply being under pressure, we need to look at solutions to decrease our operating costs and, with WILO, we can offer this.

WILO’s highly efficient variable speed drive (VSD) products offer low kilowatt consumption, resulting in high energy cost saving, water saving and a longer lifespan. What recent projects have you been involved in and what did you supply?

Eikenhof Dam, G rabouw:

• 3 split case pumps – the SCP200-460 – HA model, which is driven by 180 kW, 380 V 4-pole motors and controlled by its VSD.

• 1 MVI9503/E/16/30kW vertical multistage pump, driven by a 30 kW, 380 V, 2-pole motor. Amoi Housing Development, Helshoogte:

A COR-3MVI1603-6/CC vertical multistage booster set, which consists of three MVI1603 – 6 booster pumps driven by three 2.2 kW, 380 V 2-pole motors. The booster set is controlled by a centralised VSD complete with a multifunctional control panel mounted on one common base. Why was your product uniquely suited to the project specs?

Due to its outstanding performance, high reliability and affordability. What does the future hold for your organisation?

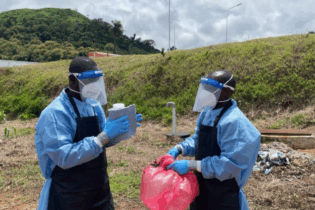

WILO South Africa is spreading its wings into Africa, where we have WILO representatives in Kenya, Tanzania, Angola and Zambia. We will be entering bigger projects and supplying more people in Africa with drinkable water. There will be numerous installations for WILO South Africa in the next few years, as we will be making a big impact in the African market and living up to our motto: ‘Pioneering for you’.