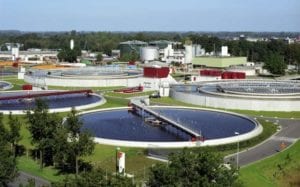

Up to 40% of the energy footprint of a city is determined by the water industry. With electricity costs accounting for some 40% of operating costs, out-of-the-box thinking is required. Royal HaskoningDHV’s solution is the Energy Factory. This system enables clients to meet their own energy needs – they may even provide surplus energy which can be supplied to others!

Royal HaskoningDHV has been involved in numerous wastewater treatment plants in Europe that have successfully been converted into energy factories. For both existing and new plants they approach the opportunities as a business case, step by step. Every step has to give return on investment within a reasonable number of years. The company is now working on its first plant in KwaZulu-Natal – providing their client with first-hand technology, experience and knowledge. “Using biogas to produce electricity has the potential to substantially reduce the carbon footprint of a wastewater treatment works,” states Siva Chetty, Water Technology: Management, Operations and Maintenance at Royal HaskoningDHV.Plants in South Africa have the potential to recover up to 50% of the energy used through methane gas produced in the digestion process. By further optimising the efficiency of the plant, producing energy becomes a fact.

“We had to come up with a new word for “wastewater” as there is no more waste: we are turning it into a valuable supply of energy and that is why we now refer to Energy Factories! All the energy needed in the wastewater treatment process can be derived from wastewater – and there may even be some surplus energy which can be given back to society,” comments Bert Bakker, Market Segment Leader: Water and Wastewater Treatment at Royal HaskoningDHV.