Retrofitting at Hartbeesfontein

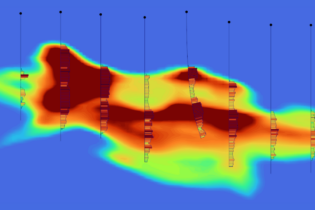

Following on from an editorial in the May/June 2013 edition, on the new HYBACS WWTW at Swartruggens, Headstream Water’s commercial director, Julian Moore, talks to Maryke Foulds about two recent HYBACS upgrades that further demonstrate the significant benefits offered by the HYBACS process. Touching base, close on a year later, it is gratifying to learn that Headstream has recently commissioned its third plant in South Africa, which is a HYBACSretrofit to upgrade the Hartbeesfontein WWTW. “While we are extremely proud of our first two plants these were greenfield new builds and not an upgrade to an existing plant. The Hartbeesfontein project is an upgrade to an existing plant to double treatment capacity from four Mℓ/d to eight Mℓ/d while also improving treatment performance to enable it to meet nutrient discharge standards,” explains Julian Moore. “This is very exciting as it demonstrates that the HYBACS process is ideally suited for upgrading conventional activated sludge plants to increase treatment capacity and improve performance. Upgrading existing treatment infrastructure is extremely important in South Africa and it is in this scenario that HYBACS is significantly more competitive than alternative technologies.” In simple terms the HYBACSprocess works as follows. It is a hybrid BNR activated sludge process where a fixed biomass process is combined with a conventional suspended biomass activated sludge process followed by conventional secondary settlement via a clarifier. It thus lends itself as an ideal retrofit technology for the widely used conventional activated sludge process. The fixed biomass reactor, which is called a SMART unit and is unique to the HYBACS process, contains a very high concentration of attached biomass and also delivers an oxygen transfer rate significantly higher than that achieved in the suspended biomass reactors. Therefore the SMART units are able to remove a high portion of the incoming COD in a very efficient manner, which when combined with the existing suspended biomass activated sludge reactors enables the plant to deal with a significantly increased load. “The HYBACS process was initially developed in South Korea in order to address the key challenges they faced due to rapid urbanisation and industrial development around existing plant sites. Thus a significant increase in treatment capacity and an improvement in effluent quality were needed but there was no space in which to expand plants. The key drivers for the development of the HYBACS process was that it needed to retrofit onto existing activated sludge plants and it needed to be able to significantly increase treatment capacity and improve effluent quality within the current plant footprint.” explains Moore. “Additional drivers were cost effectiveness, energy efficiency and the removal of odour, particularly important given that high density accommodation surrounded many of the plant sites in the cities.” The Hartbeesfontein upgrade was urgently required due to the increased flow into the existing plant combined with the higher loading on the plant from a local abattoir. The upgrade to double treatment capacity to 8Ml/d is being achieved with a HYBACS design that involves the installation of 8 SMARTunits upstream of the existing suspended biomass activated sludge reactors. Additional modifications to the existing plant infrastructure include:- the conversion of the PSTs to Anaerobic tanks for enhanced biological phosphate removal

- increasing oxygenation capacity in the aerobic reactor with an FBDA system

- the construction of a new clarifier.