“This past year has undoubtedly been a tough year for the polyolefin recycling industry in South Africa and around the world. Whilst lower virgin resin prices had an impact in South Africa, they were fortunately offset by the weakening Rand,” said Mandy Naudé, Chief Executive Officer of POLYCO.

“This past year has undoubtedly been a tough year for the polyolefin recycling industry in South Africa and around the world. Whilst lower virgin resin prices had an impact in South Africa, they were fortunately offset by the weakening Rand,” said Mandy Naudé, Chief Executive Officer of POLYCO.

“However, local recyclers of polyolefin plastics also had other challenges they needed to contend with during 2015, including load shedding, expensive electricity costs, water shortages and a general downturn in the economy,” said continued.

Naudé was addressing the association’s board members the company’s recent AGM.

Recycling sector under pressure

The low market demand, together with rising costs, has made the recycling sector a tough space to operate in. The impact of these difficult trading conditions were severely felt by the POLYCO project partners, who reported lower than expected recycling volumes for their financial year ending 31 December 2015.

“We had hoped that the New Year would bring improved market conditions, but the first quarter of 2016 saw the worst ever demand period in the last 10 to 15 years in South Africa. The official 2015 recycling statistics have not yet been released, but early indications are that recycled polyolefin volumes have remained static year on year, at approximately 171 000 tonnes,” she said.

Looking at the positive

However, all is not doom and gloom according to POLYCO. The 171 000 recycled tonnes positively contributed in excess of R1.7 billion to the country’s GDP. The total plastics recycling industry contributed in excess of R2.85 billion to GDP in 2014 and created over 53 000 employment opportunities.

“This is something of which we can all be immensely proud. We must also bear in mind that recycling is a commodity-based business which is cyclical in nature. Whilst the current conditions might be tough, we have developed a clear-cut plan of action that will help us build a much-needed robustness into the industry, so as to be ready for when the market turns again,” Naudé said.

Taking action

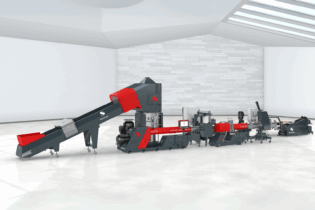

POLYCO is now working even more closely with recyclers in an effort to address and solve some of the biggest stumbling blocks, such as dirty post-consumer materials (due to a lack of effective separation-at-source initiatives), ageing and inefficient equipment, untested quality and an inconsistent value-chain.

Similar steps are being taken with the other role players in the recycling value chain in order to help them overcome their challenges and move towards more sustainable supply chain processes.

However, POLYCO is also calling on brand owners to become involved with their current initiatives in order to create a strong, sustainable circular economy which eliminates waste.

“This past year has undoubtedly been a tough year for the polyolefin recycling industry in South Africa and around the world. Whilst lower virgin resin prices had an impact in South Africa, they were fortunately offset by the weakening Rand,” said Mandy Naudé, Chief Executive Officer of POLYCO.

“This past year has undoubtedly been a tough year for the polyolefin recycling industry in South Africa and around the world. Whilst lower virgin resin prices had an impact in South Africa, they were fortunately offset by the weakening Rand,” said Mandy Naudé, Chief Executive Officer of POLYCO.