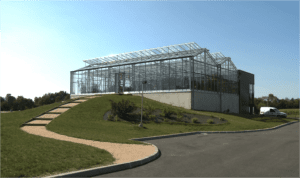

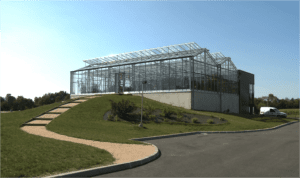

A 6000 PE Organica WWTP in a highly visible tourist region in Le Lude (Loire Valley), France

At this year’s WISA 2016 Conference, Murray&Roberts Water announced that it had acquired the license agreement for the ground breaking wastewater treatment technology developed in Europe by Hungarian architectural and engineering experts Organica Water.

“We’re extremely proud of this partnership, which gives us a unique edge in the local wastewater treatment sector. The technology has been proven in countries like France, China, Indonesia and its place of origin, Hungary. We see it having still more potential in Africa, with its rapidly growing cities as well as an increasing need for upgrading aging infrastructure and energy conservation,” comments Harry Singleton, operations executive, Murray & Roberts Water.

In a presentation delivered at WISA 2016 by Bertie Steytler, director of Prodromos Technologies – Murray & Roberts’ technology consultant – conference delegates learned more about this concept, which uses natural root systems along with root-mimicking media for a process that can be carried out in urban settings with no bad odours…all this in a structure that is simply stunning – effecting what Steytler describes as “an improved psychological footprint”.

Paradigm shift

Organica’s wastewater treatment works (WWTWs) are called “water reclamation gardens” by Organica Water cofounder, Attila Bodnar, because they look like botanical gardens rather than traditional works. Enclosed in glass houses or attractive but simple shading structures to protect plants from extreme weather, these gardens boast a number of benefits, including better treatment characteristics, smaller physical footprint, lower operating costs, and positive aesthetics requiring no buffer zone. This ensures higher water quality; no reduction in the retail value of nearby properties; resource savings, including energy and costs; and an affordable upfront investment.

“The latest in Food-Chain Reactor (FCR) technology integrates fixed-film activated sludge processes (IFAS). FCR-IFAS solutions have developed over the last decade to become highly successful and sustainable. Organica’s application of these water reclamation gardens stands out because of these WWTWs’ potential to change mindsets about wastewater reuse and recycling, completely eliminating the urban planning barriers of locating this type of infrastructure, enabling placement in the middle of neighbourhoods close to where the wastewater is generated,” explainsPéter Varga, business development manager, Organica Water.

Urban solution

Since water reclamation gardens are attractive and don’t generate unpleasant odours, they overcome the need for municipal zoning requirements. This makes them ideal for construction in cities.

Varga explains: “In today’s cities, urbanisation causes populations to increase rapidly – Gauteng, for example, about 300 000 people are added per annum. This requires almost a new city’s worth of infrastructure to be built in Gauteng every year, while existing water scarcity is further exacerbated.”

Presenting a massive cost-saving opportunity, water reclamation gardens reduce the need for expensive underground piped infrastructure to carry sewage out of cities. Further, if the technology is used to polish water at the final stage of treatment, it can also reduce spend through water treatment bringing fresh water to urbanites.

“Sustainability means treating waste as close as possible to where it’s generated,” adds Varga. “This is why the technology also represents a contribution to the circular economy.”

Innovative, Sustainable, simple technology

In a process that Bodnar has referred to as “water alchemy” to describe our changing relation with wastewater infrastructure, biomass is significantly increased in the water garden’s reaction chambers via this rich habitat made possible by plant roots so that, instead of providing a breeding ground for the usual 800 species of microorganisms typically present in traditional WWTWs, a substrate is provided that is capable of housing over 3000 species!

“In a conventional WWTW’s reaction chamber, the activated sludge concentration is between 3 kg and 5 kg per cubic metre. Filament-like structures of plant roots and Organica’s specialised media increase the surface areas for sludge attachment to take place, while also creating a better habitat for microorganisms to live and multiply. This accounts for much greater biodiversity while also facilitating a biomass increase to as much as 12 kg to 15 kg per cubic metre.

“In addition, water clarity is improved within the reactors resulting in more efficient oxygen transfer. Clearer water can dissolve much more oxygen, meaning that less air and, therefore, less power is needed by the system,” explains Varga.

A better biomass-to-volume ratio means the system can be up to 50% smaller in physical footprint than conventional treatment plants. This makes the purchasing of urban land for plant placement more affordable. A lower geographical footprint also makes the technology ideal for retrofit projects, because the FCR-IFAS process can be implemented at existing works to postpone or even prevent the need for building new reactors in areas where populations have outstripped the capacity of their local works.

Better living spaces

Varga, adds, “It’s not only the biofilm and subsequent increased biodiversity of the bugs within the sludge that results in more effective treatment and odour elimination; we also employ a strong architectural team at our firm and our plant’s design features optimised ventilation, among other innovations.

“This is why it is possible that citizens in China for example, where are plants are located literally in the midst of neighbourhoods – can sit next to these gardens and eat their lunches quite comfortably, enjoying a green break in the otherwise concrete environment.”

Varga was also available after Steytler’s paper to discuss various plants around the world, citing one in his native Budapest that grew bananas, which he and visiting engineers had eaten during their lunchbreaks while viewing the site.

Market opportunity

South Africa is a country committed to reducing pollution, being more energy efficient and conserving its precious water resources. Water reclamation gardens accommodate all of these needs.

As the number of Organica facilities increases globally (there are over 80 today either under construction or in operation), historical commercial and operational data is becoming increasingly available; what these data are showing is that water reclamation gardens continue to be the leading technology in energy reduction – lowering power consumption by up to 30%.

“Imagine if every wastewater treatment plant used 30% less energy. This technology represents an opportunity to make wastewater treatment more energy efficient, subsequently lowering air carbon footprint on a national scale,” points out Varga.

As a result of the “food chain” that establishes with the presence of more complex organisms that can survive in the root-zone habitats excess sludge is also reduced in the process, further lowering operating costs.

Numbers aside, perhaps most importantly the attractiveness of an Organica facility has the power to change mindsets about wastewater reuse. It’s a way to overcome the “yuck” factor, bringing wastewater treatment to the middle of cities, making abundant water resources available through manageable reuse networks.

Flexibility

“We can and have built water reclamation gardens in urban and peri-urban areas. In warmer climates, we have even forgone the glass structures around planted reactors, replacing them with simple shading structures.

“The system uses indigenous flora and otherwise locally available plants. While it is possible to grow plants of economic value, the facilities are meant to fit into smaller areas and not provide horticulture production; this solution is an urban one and the main advantages will emerge most prominently in urban settings, where space is of great value” explains Varga.

Partnership forward

“We don’t build these plants ourselves. Local South Africans will be building the plants; 90% of the equipment will be locally sourced. We’ve been working for almost two years with Prodromos to establish the optimum partner to roll out our technology in a way that reflects our corporate goals and values,” explains Varga.

“From our first meeting with the folks at Organica, I think we all sensed an alignment of cultures and synergies, which made all parties feel comfortable taking the next step,” adds Singleton.

“We’ve agreed on our combined vision from the beginning – sometimes two organisations just gel, and Murray & Roberts Water was ideally placed as a small division within a large construction giant to use the energy of the former with the support of the latter to deliver on Organica’s environmental promise to the standards for which both brands are renowned,” concludes Singleton.

After the Murray & Roberts-Prodromos-Organica presentation, Singleton, Steytler and Varga were swamped by engineers and municipal technicians wanting to know more about the technology and its local applicability. Judging from high levels of interest, South Africa will be rolling out its own water reclamation gardens very soon. Watch this space for details.