Brent Mahoney* of Averda SA recently returned from an incredible, year-long adventure – spanning three continents – where he gained a global perspective on localised landfilling.

Brent Mahoney* of Averda SA recently returned from an incredible, year-long adventure – spanning three continents – where he gained a global perspective on localised landfilling.

While Averda was establishing itself as a leading waste management brand in South Africa, you participated in a year-long work exchange programme. What were some of the countries you visited and what was the purpose of the exchange?

Brent Mahoney, manager: Logistics, Sales and Landfill, Averda SA

I spent time working in Beirut in Lebanon, Abu Dhabi and Dubai in the UAE, Casablanca and Rabat in Morocco, Angola, London and Oman. My travels exposed me to real, in-country business dynamics, and is probably the best practical MBA-type experience I could have ever asked for.

This research exercise was intended to give me exposure to the Averda global footprint, operations, systems and culture. It was important for me to see the type of technical competencies Averda operates with, their service offerings, and to witness how they mobilise and operate in countries with different economic markets, conditions and challenges. All of these countries are different, and a different formula is required to operate in each market. As the Logistics, Sales and Landfill manager for South Africa, I was particularly interested in how Averda mobilises its resources across the world, particularly in the immensely challenging environments of emerging markets.

How did the other African countries’ waste management and landfilling practices compare to South Africa’s?

South Africa is significantly ahead of the rest of Africa when it comes to standards, procedure, enforcement and compliance in waste management, but there is clearly a desire to improve standards and develop better infrastructure. Worth noting is that Angola has constructed one of the biggest landfill sites in the Africa.

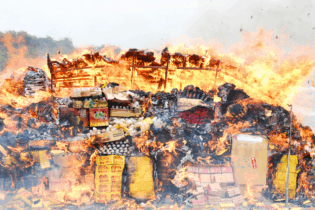

Nonetheless, South Africa is ahead in terms of operating, design, permitting and compliance of hazardous landfills and medical waste treatment. One of the biggest challenges presented in Africa is the lack of hazardous waste landfill sites, treatment facilities and incinerators. The other African countries are either exporting hazardous waste, or mixing hazardous waste streams with general waste on general waste sites.

The key driving factor and differentiator in South Africa is the regulation governing the waste industry and most importantly the enforcement and management of the promulgated law.

South Africa complies with European standards and, in my view, is a leader in sub-Saharan Africa.

Moreover, our compliance and enforcement of segregating waste, delisting, analysing and sorting at the source are significantly advanced when compared to the rest of Africa, and in line with global best practices.

You also visited a number of sites in the Middle East. How do waste management challenges differ between South Africa and some of those countries and why?

In the Middle East, there are limited weather elements to contest against in terms of rain, mud and wind. The region’s desert environment, extreme heat and world-class infrastructure enable more effective collection systems and very little leachate.

Averda’s tried and tested system of vehicles, fleet telematics, collection, weighing, billing systems and software is highly advanced and sophisticated. The company’s collection, sales and administration systems are all automated and it’s encouraging to know that Averda SA has access to advanced and proven technology. This was definitely a highlight of the trip in terms of learning and skills exchange.

Further, Averda has world-class landfill sites all managed, engineered and designed in terms of excellence and continually strives to lead in delivery to ensure the brand remains a market leader in emerging markets. For example, the Beirut landfill site has 18 gas wells permanently converting methane gas into energy for use by the local residents.

One thing I did notice is that the Middle East is yet to enforce an incentive for recycling, and landfilling is still a very affordable and cost-effective option. Laws and penalties are being devised to encourage and incentivise sorting at source and reducing waste to landfill.

This is an example of how law and industry change, ultimately driving service providers to re-engineer a more comprehensive integrated service offering to the market. In the Middle East, the landfill sites are world-class, and managed and designed by some of the leading waste management companies and engineers in the world.

Also, Middle Eastern landfill sites have no waste pickers. The climate conditions of extreme heat make it challenging to operate in the Middle East, as temperatures reach up to 50°C. Enforced law disallows drivers or vehicles to work on the roads and landfill sites during the midday heat, forcing staff to work at night.

Similarly to all over the world, businesses in the Middle East are also seeking to find the best solution for the best price. However, the challenge is that alternatives and innovation don’t always work at the cheapest price.

You mentioned Averda’s Beirut landfill as being particularly advanced. Can you describe the volumes and some of the innovations at the site?

In Beirut, Averda collects about 7 000 tonnes to 8 000 tonnes of waste a day, using 550 trucks. The two respective material recovery facilities process 3 000 tonnes a day of municipal solid waste and recover 1 000 tonnes of recyclables a day. About 20 000 tonnes per month of wet waste is converted into compost and sold to farmers.

All low-density plastics are diverted to a pelletising facility and suitable wood briquetted into boiler fuel. The Averda Engineering Division has an optical and state-of-the-art laser refuse-derived fuel (RDF) plant piloting and sampling RDF fuel and to ensure accurate, calorific consistency, production inputs and outputs for market execution.

Once again, the above highlights the pride and accuracy in Averda’s technical competency and engineering excellence.

The abovementioned benchmarks are only some of the milestones and handling capacity highlights of the overall Averda Group. In Beirut, the Averda team collects in a day what Averda (Gauteng Division) collects in a month.

What do Averda’s intercontinental network and experience bring to the table for waste management in Africa?

Averda’s global network and proven technology offer 50 to 60 years of experience in the industry and, by the same token, Averda SA has access to an expansive, proven technical capability and competency.

The company’s local iteration is given access to engineering expertise in Beirut for design and engineering excellence. The London Business Development and Technical Office has mechanical and aeronautical engineers available to the Averda Group for all technical aspects to analyse design, financial feasibility and longevity, and commercial due diligence before any projects and technical procurement are approved by the global board and shareholders.

Since tried and tested systems are crucial when you’re working in emerging markets, Averda brings reliable technological engineering competencies, which have been adapted to its business over the years.

Moreover, the company has dedicated engineering experts working on solutions to provide and ensure a high technical standard. One of the company’s core values, as stressed by CEO Malek Sukkar, is that Averda employs the best people, and partners with leading universities in the world to headhunt and ensure mapped-out career paths for its people. Averda also works closely with local communities to employ, train and educate its workforce to have a lasting legacy and help, in some small way, to address local youth employment challenges.

You mentioned that Averda’s presence in South Africa will raise the standard of local waste management. How is this being achieved?

Averda is the first waste management company that has dedicated engineering and design departments, and it upholds high standards, delivery, longevity and credibility wherever it operates. Vlakfontein is an example of the Averda standard, aligned to global best practice and local laws.

*Brent Mahoney is the manager: Logistics, Sales and Landfill at Averda SA.

www.averda.com

Brent Mahoney* of Averda SA recently returned from an incredible, year-long adventure – spanning three continents – where he gained a global perspective on localised landfilling.

Brent Mahoney* of Averda SA recently returned from an incredible, year-long adventure – spanning three continents – where he gained a global perspective on localised landfilling.