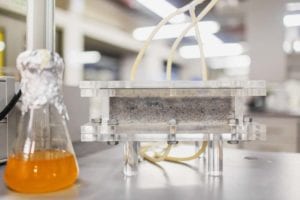

The South African waste recovery market is set for a major paradigm shift following the unveiling of the first world’s first bio-brick grown from human urine.

The bio-brick, which is the handy work of researchers at the University of Cape Town, is created through a natural process called microbial carbonate precipitation which is similar to the way seashells are made. “Loose sand is colonised with bacteria that produce urease. An enzyme, the urease breaks down the urea in urine while producing calcium carbonate through a complex chemical reaction. This cements the sand into any shape, whether it’s a solid column, or now, for the first time, a rectangular building brick,” explains Dr Dyllon Randall, study supervisor and senior lecturer in water quality engineering t UCT.Low carbon, zero waste

The development is good news for the waste recovery and upcycling sector as well as the environment because unlike traditional bricks the bio-bricks are made in moulds at room temperature cutting the vast quantities of carbon dioxide produced during production. In addition to being a low carbon product the bio-brick process produces by-products which are important components of commercial fertilisers. The urine is collected in novel fertiliser-producing urinals and used to make a solid fertiliser. The remaining liquid is then used in the biological process to grow the bio-brick and the by-product from this process is then used to make another type of fertilizer.The project was unveiled by master’s student in civil engineering Suzanne Lambert. She was supervised by Dr Dyllon Randall and assisted by civil engineering honours student Vukheta Mukhari, who was supervised by Professor Hans Beushausen, also from the civil engineering department.