Delivering potable water to every household is one of the primary objectives in South Africa and worldwide. That requires sustainable and engineered responses that are interdependent on public and private sector collaboration. IMIESA speaks to NJ Bouwer, executive at NuWater, about their workable solutions based on selecting the right choices.

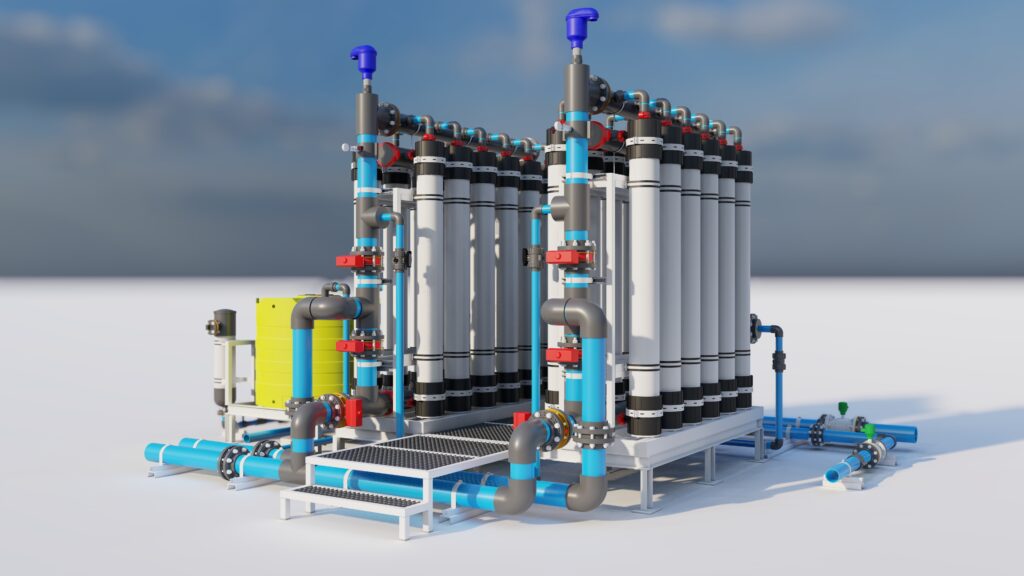

One of the key drivers for success in any sector of society is the ability to understand and embrace technological evolution. Within the water sector, for example, advances in treatment processes like ultrafiltration (UF), reverse osmosis (RO) and a variety of oxidation technologies are delivering revolutionary benefits. They form the core of NuWater’s technology suite, specialising in scalable modular automated package plant solutions for the water, wastewater and desalination markets. The advantages of RO and UF include reduced process costs, since both systems use membrane technology, substantially negating chemical dosing requirements. Compared to conventional treatment plants, UF processes and oxidation technologies are also far better suited to dealing with the higher degree of raw water variability induced by climate change and downstream pollution. NuWater’s solutions are benchmarked against international best practice technologies with proven applications for private and public water users. “Within the municipal space, our objective is to ensure that their engineering departments are kept informed on the best choices from both environmental and life-cycle costing perspectives,” Bouwer explains. “Conventional process technologies that are decades old cannot compete with modern-day alternatives and the advancements in membrane technologies in terms of final treated water quality.” ADDITIONAL READS: NuWater: Tapping tomorrow While conventional water and wastewater plants cost millions to build, NuWater’s compact modularised ‘plug and play’ type solutions are far more affordable and relatively quick to build, deploy and commission. An operating life of up to 40 years is achievable, and NuWater plants are available on a rental basis, as an outright sale, or supplied in terms of build-own-operate (BOO) and build-own-operate-transfer (BOOT) agreements. Many options exist to solve current problems. “A conventional concrete treatment works might last 100 years or more, but that’s not what South Africa’s looking for right now as they take too long to establish and incur great costs. We need more immediate, affordable solutions that address the growing potable water supply gap,” says Bouwer. Rising water demand, ageing infrastructure and PPPs Population growth and urbanisation are placing increasing strain on ageing treatment plants, now frequently overloaded well beyond their design capacity, and not always process compliant. Increased water demand also puts available water allocation capacity at risk, without factoring in non-revenue water (NRW) losses. NRW estimates indicate that between 25% and 50% of treated potable water doesn’t reach the consumer, primarily due to leaking pipes. This places further financial strain on municipalities in terms of lost billings, plus it’s a terrible waste of water. “Our ageing infrastructure places South Africa’s socio-economic future at risk if we don’t implement quick wins. In my view, government’s primary focus should be on repairing, replacing and upgrading South Africa’s national water transmission network. In turn, government and municipalities should embrace the advantages of oursourcing water and wastewater treatment to private sector specialists – a trend where NuWater sees a positive mindset shift,” states Bouwer. This view is supported by the public-private partnership (PPP) model envisaged in the South African Infrastructure Fund and the allied Economic Reconstruction and Development Programme. ADDITIONAL READ: Keeping it clean Local municipal partnerships A prime example of a PPP in practice is NuWater’s agreement with various local municipalities to operate several UF package plants. These are being run as either BOO or BOOT plants. One such municipality’s total potable water output is around 120 Mℓ/day, with NuWater contracted to deliver a significant portion, with raw water sourced via the local dam. This water is characterised by high concentrations of heavy metals (typically iron and manganese), as well as sulfates.“Our analysis of this municipality’s conventional plants showed that there was plenty of opportunity for optimisation and improvements in efficiency. Essentially, the existing process could not bring the water into specification at the best cost, plus the existing process configuration and dosing strategies posed a risk of forming harmful by-products, which are potentially carcinogenic,” Bouwer explains.

The UF process, by comparison, eliminates suspended solids and rejects viruses, and bacteria. Pre- and post-oxidation processes reduce the threat of forming harmful by-products and ensure the water is sanitised for distribution.

of KwaZulu-Natal. NuWater is responsible for inbound and outbound water treatment. Potable water will be sourced from seawater intake and wells, while the treated effluent will be reused via a secondary network for applications

like irrigation. Industrial Industrial wastewater and reuse are further core markets for NuWater, with PPP potential. “Similar to discussions on wheeling tariffs for privately owned solar installations, we see the potential for something similar in the industrial wastewater treatment space, separate or in collaboration with municipal infrastructure. As municipal treatment works become overloaded, it’s imperative that industry has a safe and sustained disposal solution for its effluent,” Bouwer explains. Conservation “In the end, conservation and management should be priority number one for all water users, whether public or private. And as a strategic partner, NuWater remains fully committed to investing in the best technologies so that municipalities are equipped to deliver world-class services,” Bouwer concludes.