Electric motors, CO2 emission reduction and lightweight construction are key issues for the automotive sector, but what about water? Automotive manufacturers use thousands of litres of water each day – making this an ideal cost-saving and sustainability focus.

By Chris Ashmore, CEO Watericon

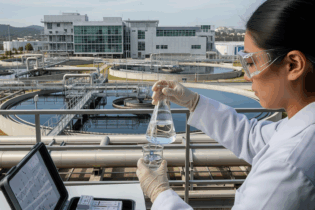

Water conservation is becoming an issue of growing importance in sustainable vehicle manufacturing – not to mention the cost savings associated with sustainable water usage. Around the world, automotive manufacturers and suppliers are collaborating in their efforts to improve the environmental performance of their organisations. Unfortunately, the true cost of using water is often misunderstood across industries, resulting in poor management choices regarding how water is used and treated. For example, the automotive sector is a major consumer of water, which is a critical component in various production processes, including paint spray booths, surface treatment and coating, hosing, rinsing and washing. Of the various automotive production processes that use water, metal finishing operations are notorious for high water consumption, but it is in the paint shop that water consumption is most significant. The painting process itself uses considerable water volumes, and processing equipment used for automotive coatings must be cleaned regularly.In addition to the use of water for these processes, there is also the matter of wastewater, which needs to be treated to high standards to meet environmental regulations. So, how do automotive manufacturing plants ensure sustainability, improve their environmental footprint and save costs when their processes rely on using thousands of litres of water each day?