Globally, up to 10% of energy used in water treatment goes towards pumping water. Grundfos believes that up to 4% of this can be saved by utilising good pumps and systems. The company has designed a range of energy-efficient, smart products spanning the full water treatment value chain to provide holistic, sustainable and effective solutions.

Globally, up to 10% of energy used in water treatment goes towards pumping water. Grundfos believes that up to 4% of this can be saved by utilising good pumps and systems. The company has designed a range of energy-efficient, smart products spanning the full water treatment value chain to provide holistic, sustainable and effective solutions.

Off the grid

To further reduce energy costs and cater for the unique requirements of rural and agricultural areas, Grundfos offers completely off-grid systems. These solar solutions include the pumps, remote monitoring and system control, solar panels, treatment systems, and components required for a complete water supply system, which can also be designed for wind power. A number of pumps are available with integrated or external solar drives, simplifying installation and service. They are fully AC/DC compatible, meaning they can run on mains power or a generator, enabling pumping at night, explains Stephan Venter, product specialist, Grundfos. Source-to-tap drinking water solutions are also available by adding an intelligent AQtap water ATM and, if required, an AQpure water treatment system to any water supply. Falling under the Grundfos Lifelink umbrella, these solutions cater to low-income communities in developing nations. Grundfos AQtap is an intelligent water ATM that addresses some of the main challenges of providing reliable and sustainable water supply in the developing world. Through an integrated platform for revenue collection and online management of water kiosks, Grundfos AQtap supports the financial viability and accountability of water service operations. This can be linked to AQpure, an ultrafiltration-based water treatment system capable of producing drinking water across four raw water categories. It is ideal for local communities and remote areas where establishing stable, reliable and affordable production of drinking water can be extremely challenging. In the Mathare informal settlement in Nairobi, Grundfos installed Lifelink automated water ATMs to enable Nairobi City Water & Sewerage Company to cut off illegal water cartels who charged residents up to 20 times more for water not guaranteed as safe to drink. The water ATMs have significantly improved residents’ lives by providing safe and easy-to-access water at a fair price. Optimal water treatment

Optimal water treatment

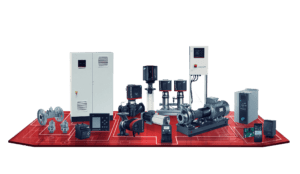

Grundfos sells a variety of products to complement customers’ water treatment solutions, ranging from pumps, polymer make-up systems, dosing and disinfection units, to control and monitoring devices. These are suitable for conventional water treatment as well as ultrafiltration, reverse osmosis and desalination.

Automation is becoming increasingly crucial in water treatment installations, particularly when it comes to optimisation and safety in medium to large water treatment systems. The inclusion of early warning and logging systems assists with plant optimisation, energy-use reduction and safe operation, and provide the necessary process and safety interlocks for operators and equipment safety, proactive maintenance and recording of plant performance, explains Katrina Zlobich, business development manager: Water Treatment, Grundfos. Grundfos offers controllers for pump protection and performance optimisation such as variable-speed drives, motor protection relays and motor controllers.

As regards water quality and safety, Grundfos’ DID water analyser offers up to three different measures on a single controller, which can be fitted with different sensors depending on process and customer requirements. This will assist in achieving accurate chemical dosing and reliable measurements and can be customised according to client needs. Dosing pumps and disinfection units can be connected directly to a DID controller, whose analogue and digital outputs can accommodate pulse and 4 mA–20 mA pumps.

Grundfos’ SMART digital dosing pumps are now available in a large scale (up to 200 ℓ/h) while higher flow rates can be achieved with the DME, DMX or DMH dosing pump ranges. A variety of accessories, such as electric mixers, tanks, pressure loading and pressure relief valves, and suction lances complement the dosing range.

Demand-driven distribution

Demand-driven distribution

Some water systems lose up to 40% of their water through leaks – a costly exercise that cannot be afforded in water-stressed countries like South Africa.

Grundfos can supply pumps and controls for the entire water distribution system, including main and local pumping stations, ensuring reliable managementof pressure zones throughout the

pipe network. To do this, Grundfos works on the principle of demand-driven distribution (DDD). Wireless pressure sensors can be installed at critical points along distribution networks, sending pressure measurements to the pumping station where a Grundfos booster-set equipped with a Grundfos CU controller receives the data and creates a model for the network. With this model, the booster-set can typically keep a lower average pressure in the critical points. By controlling the pressure in the system and reducing water hammer, Grundfos’ DDD solution offers a lower operation cost, lower leakage rate in the network, fewer pipe bursts, more stable supply to end users and more automated optimisation of network. On the other side of the coin, Grundfos’ booster units provide constant pressure regardless of flow fluctuations for high-rise buildings, irrigation systems and booster substations. These range from basic units to advanced systems, depending on the application and requirements. Pump curve data is used to determine the most efficient speed and the required number of pumps, continuously optimising energy consumption. Pump speed is continuously monitored to keep the required pressure constant.

Control and monitoring

“You have to measure to know,” says Venter, and Grundfos’ in-house Scada system, Grundfos Remote Management (GRM), allows customers to do this. GRM gives clients the benefits of an already established, advanced Scada system without the large capital costs and maintenance associated with establishing their own Scada. The web-based and soon-to-be-cloud-based GRM can be used on all of Grundfos’ automation-compatible products. The system allows customers to manage their pump systems from anywhere in the world in a cost-effective, easy manner. It provides a complete status overview of the entire system, offers live monitoring, analysis and adjustments, and assists with proactive maintenance based on actual operating data. For those without access to a computer, Grundfos GO is a downloadable mobile phone application that allows you to access your pumps and systems from your smartphone. “Technology is advancing and moving towards the internet of things, so our devices have to have full communication capabilities and we are always looking at ways in which we can connect all of our products to GRM and Grundfos GO,”says Zlobich. For those with an existing Scada system in place, Grundfos’ GENIbus open data communication protocol can be used to connect Grundfos pumps. With its wide variety of products available, Grundfos is all about bringing the best solution to the table. “It’s about more than selling a pump, it’s about selling a solution,” concludes Venter.