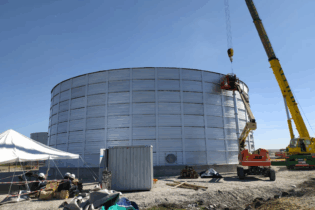

Membrane technologies like ultrafiltration can ensure exceptional final water quality and, with the right company, an improved operational experience.

By Herman Smit, managing director of Quality Filtration Systems Most conventional water treatment systems require constant monitoring and daily operator decisions regarding plant operation. Ultrafiltration (UF) membrane processes offer a fully automated process that reduces operator involvement. With limited skilled operational staff available in South Africa, a more automated process offers many benefits. However, reduced operator involvement is not necessarily in conflict with the employment of labour. The improved skills required to operate UF plants provide an opportunity for the existing operators to improve their skill levels through training and studying, and treated volumes can be increased with the same number of operational staff. UF systems are ideal for new installations or for upgrades to existing filter systems or clarifiers, cutting operating costs and decreasing the plant footprint, while delivering exceptional value over the entire system life cycle.Instrumentation and control

Standard UF membrane systems are supplied with feed and filtrate pressure transmitters and may also have other local instruments such as flow, temperature and pH sensors, which are used to monitor the operation of the system. A programmable logic controller controls all operational functions, while a human machine interface (HMI) module allows adjustments to be made to the operational configuration settings remotely. The operator is allowed limited operational changes but can make use of the HMI to operate the system and log important operational data. If the system operates outside normal limits, a warning is typically generated. Operating outside wider limits can generate a shutdown alarm, which stops the system, reducing the risk of damage to system components.Extending membrane lifespan

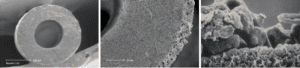

Short reverse flow of filtrate removes the retained solids from the membrane fibre surfaces. Liquid backwash waste is then drained or flushed from the system to the backwash waste disposal system. The feed and filtrate sides of the system are then refilled in a process like start-up, and the system then returns to service.Depending on feed quality, the control system typically initiates an automatic backwash every 20 to 60 minutes of filtration. The backwash cycle typically takes about two to three minutes to complete. During each backwash, the waste solids are completely drained from the membrane surface, which eliminates solids accumulation and biological fouling.

When the build-up of foulants on the membrane modules increases the transmembrane pressure (TMP) or reduces flow rate, a clean-in-place cleaning cycle is usually required. Cleaning may also be initiated simply on an elapsed-time basis, such as once per month or every six weeks, even if TMP values have not reached a high level. This is a particularly useful strategy to maintain cleanliness in potable water systems.