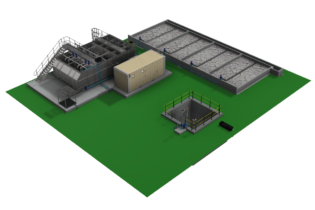

In line with a R187 million expansion project to improve the ageing infrastructure in Buffalo City Municipality, the Reeston Wastewater Treatment Works in East London has undergone an upgrade to increase its capacity to 12.5 Mℓ/day.

As part of the Reeston Wastewater Treatment Works (WWTW), QFS was responsible for the fast delivery and implementation of an I-BOx® 7010 odour control unit. The odour control was installed for the inlet works section of the plant, as these areas are highly prone to hydrogen sulfide (H2S) generation due to the turbulence created through degritters, screens and various other equipment. The turbulent water allows the gases contained within the water to be released as the water follows its course though the inlet works. The H2S released in these works can be a severe safety concern for the roughly 80 personnel operating at the Reeston WWTW, with high concentrations leading to severe safety risks of operators, as per Table 1.| H2S concentration | Toxicity | Effect |

| 0.1 – 3 ppm | Odour threshold | |

| 3 – 10 ppm | Offensive odour | Rotten egg smell |

| 10 – 50 ppm | Headache, nausea, throat and eye irritation | |

| 50 – 100 ppm | Eye injury | Leads to serious eye injury |

| 100 – 300 ppm | Conjunctivitis, respiratory tract irritation, olfactory paralysis | Coughing, eye irritation, loss of smell after two to five minutes |

| 300 – 500 ppm | Pulmonary edema | Imminent life threat |

| 500 – 1 000 ppm | Strong nervous system stimulation apnea | Loss of consciousness, death possible in 30 to 60 minutes |

| 1 000 – 2 000 ppm | Death | Rapid unconsciousness |