Our very first Water Warriors feature introduces Gerrie Brink, his company – AQUAffection – and the #SurplusWater2025 movement that they started.

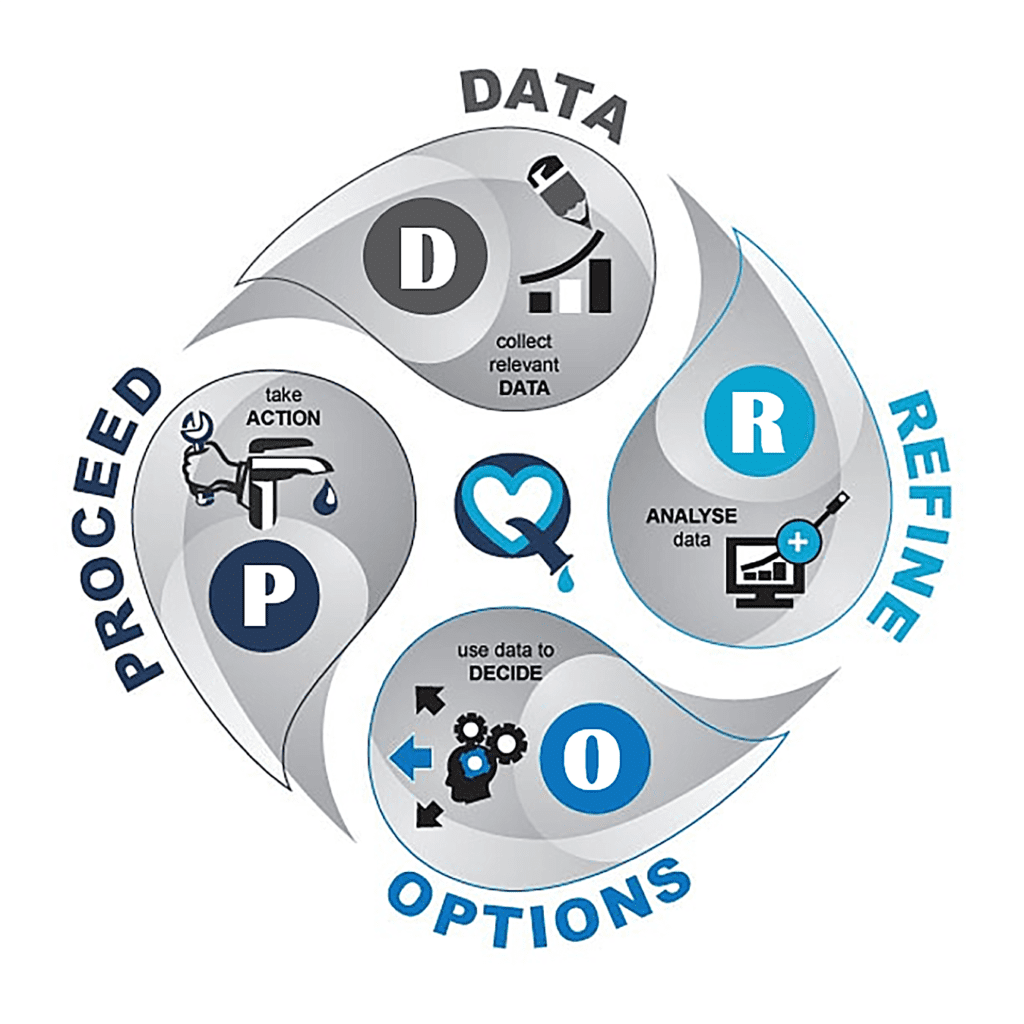

With a growing global population, the demand for potable water increases daily. South Africa has moved from a water-stressed country to a water-scarce one. It is predicted that South Africa will form part of the ‘extreme scarcity’ category by 2025. “When I heard this prediction, I started to think about what could be done to turn South Africa’s water situation around. We cannot simply sit around and accept that South Africa will fall into the ‘extreme scarcity’ category. We have to do something now,” says Gerrie Brink, managing director of AQUAffection. Over one billion liters of water saved #SurplusWater2025 is an initiative born out of Brink’s vision to effect positive change in South Africa’s water industry. To date, 31 companies have joined the movement, 473 meters have been installed, and over a billion litres of water have been saved. The current daily savings are running at close to two million litres, with this number growing as more companies join the movement. “The movement is about collaboration. It is about pooling resources together. I believe that if everyone focuses on their core expertise, we can make a far bigger impact in a shorter amount of time. We need to stop competing with each other and start complementing one another. #SurplusWater2025 is about sharing knowledge,” explains Brink. Monitoring “It all starts with monitoring – you cannot manage what you cannot measure. Water meters are a form of measurement, but they are a snapshot where a reading is taken at the beginning and the end of a month – giving a total consumption of water in a month. It does not give insight into what makes up the water consumption (toilets, irrigation, water coolers, etc.) or when there are peak flows, or how much water is used during a particular period in the day.” AQUAffection researched a number of monitoring tools. “There are many hardware and software options, but they seldom integrate seamlessly with each other. We then found WRP Consulting’s Zednet water demand management solution. It can show different parameters (tank levels, rainfall, flow patterns, borehole water, quality monitoring, electricity consumption) on the same display. It is customised to the needs of our corporate clients,” adds Brink. By using the monitoring tool, all water savings are easily reported daily, and a cumulative number displays savings since the start of the project. This assists corporate in calculating money saved versus money spent on water-saving initiatives. The water savings contribute towards the #SurplusWater2025 initiative. The DROP Approach AQUAffection uses the ‘DROP Approach’ when tackling a water problem. 1) Data: Collect all relevant information/data to determine the historic daily demand of the site. Understand the history of water demand from water bills and meter readings. AQUAffection determines if the site can save water. This also establishes the baseline against which future demand will be measured to calculate savings. 2) Refine: Install electronic monitoring devices – also called automatic meter reading devices – to refine and better understand the site’s water demand profile; monitor site consumption to determine flow profiles and demand. 3) Options: Determine the options to lower demand (leaks, efficiency devices, system optimisation), as well as options for backup systems and alternative sources. 4) Proceed: Proceed with the implementation of the identified options. “DROP forms a continuous loop to reduce the water footprint. For example, once a leak is repaired, then data is collected and the whole process starts again. We aim to achieve the biggest impact with the lowest capital outlay and without impacting on anyone’s comfort levels.” AQUAffection first works towards reducing the client’s water demand before setting up backup or alternative water sources. This ensures a lower-cost backup system, as it is always smaller than initially estimated – corporates therefore save money, mitigate risk and are more sustainable. “Everybody is focusing on alternative water sources, building dams, desalination and wastewater treatment. A lot of money is spent on treating water that is then directed into a system that is 80% inefficient. We need to create an efficient system before investing in backup or alternative water sources,”adds Brink.

Patented flushing mechanism

Brink did an MBA at the University of Stellenbosch Business School with a research paper on ‘Factors influencing water demand in commercial buildings’. “If there are no cooling towers or water irrigation, 90% of water consumption is from toilets. And if a mechanismgets stuck in a toilet, it can flush over

700 litres an hour. This is why AQUAffection has developed a patented outlet valve mechanism together with Dutton Plastics Engineering, which is available at various outlets like Plumblink and Chamberlains.” Tests have shown that, by changing the outlet valves on all of the toilets, one can reduce water in commercial buildings by up to 80%. “This is what I mean about collaboration – if AQUAffection decided to manufacture the outlet valve ourselves, it would have taken years to bring it to market. But by working with Dutton Plastics Engineering, we can readily use the outlet valve now while focusing on our core business – reducing water consumption in commercial buildings,” says Brink. With the calculated water savings and available data, AQUAffection is influencing greenfield projects too. It has a dedicated Wet Services Department that takes everything learned from AQUAffection’s retrofit projects and assist developers and architects with water-efficient buildings. If you want to join the #2025SurplusWater movement, visit: https://surpluswater2025.com. Some of the companies taking part in the #SurplusWater2025 movement • Atterbury • Attacq • ADvTECH • Emira • Steenberg • Fortress • OUTsurance • We Buy Cars • Blue Bulls • Dutton Plastics Engineering • Lecico • SBS Tanks • WRP Consulting • Rainbow Reservoirs • Moolman Group