Companies that consistently perform and deliver exceptional customer service in their niche markets have an infinite life. A prime example is the legendary history of APE Pumps and sister company Mather+Platt, which have been pump leaders in South Africa since 1952. General manager John Montgomery profiles some of the key men and women who continue to shape the group’s future. Beyond being an original equipment manufacturer (OEM), the group is graded as a 7 ME contractor in terms of the Construction Industry Development Board rating system, operating across South Africa, as well as in Southern Africa, with a permanent office in Lusaka trading as PSV Zambia. “Since 1952, the group and its personnel have been involved in a wide variety of South African and African infrastructure and industrial projects, developing a rich legacy of experience,” says Montgomery, adding that today the South African and Zambian arms form part of the global WPIL Limited group of companies, all focused on OEM

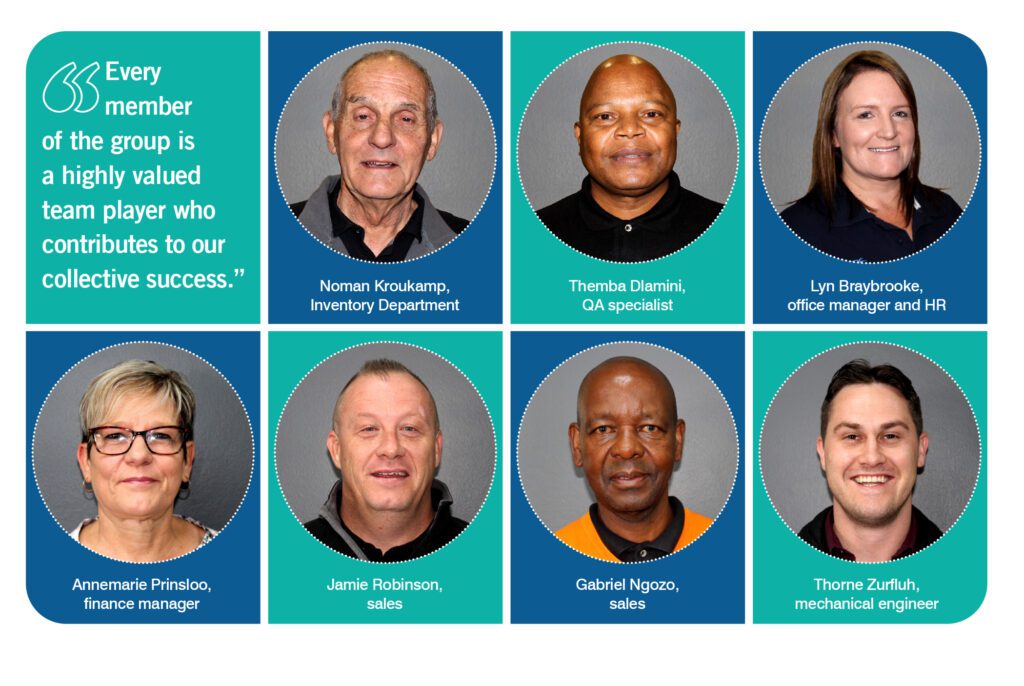

pump solutions. “Every member of the group is a highly valued team player who contributes to our collective success. We invest extensively in technology, training and personal development, backed by apprenticeship and mentorship programmes. As a result, we have exceptionally high employee commitment levels, which is why so many of our staff stay with us through to retirement,” Montgomery continues.

An employee with 50 years’ of service

Currently, Noman Kroukamp, aged 75, is the group’s longest-serving employee, now working four days a week in the Inventory Department where he supports the Sales, Planning, Manufacturing and Construction divisions. He has never retired, and remains with the group because of their recognition of his lifelong knowledge, expertise and dedication, passing on the invaluable lessons learnt to young members coming through the ranks. His journey as a much younger man began in 1973 when he joined what was then referred to as Amalgamated Power Engineering – then headquartered in Bedford, England, and subsequently trading independently today as APE Pumps in South Africa following a buyout. Prior to that, he worked for International Combustion Africa as a pupil engineer, in the process completing his NTC 5 and NTD studies in mechanical engineering, with a specific focus on pumps and heat engines. “I’ve had a passion for pumps ever since, and it’s been an amazing experience seeing the group grow in brand strength, backed by concerted research and development (R&D). From inception, custom designs were always part of our offering, along with our standard range. Every drawing is on record since 1952, enabling us to refurbish or remanufacture any one of our pump models for all industries,” says Kroukamp.

A series of acquisitions

From the 1950s, APE in South Africa embarked on its own acquisition path, which included the revitalisation of the Mather+Platt series in 1954. The latter has a pedigree dating back to the UK’s First Industrial Revolution in the late 19th century. Other subsequent acquisitions included the Sangus Engineering turbine pump range, and the Fairbanks Morse vertical turbine series, complementing APE and Mather+Platt’s horizontal, vertical, split and end suction pump series. Some of the key horizontal split pump installations at the time included systems for the roll-out of Eskom’s greenfield Duvha and Hendrina power stations. Allied to this were installations for some of Johannesburg and Pretoria’s high-rise buildings. There were many other subsequent acquisitions, such as the Robuschi pump offering, focusing on the petrochemical market, which was subsequently unbundled from the group. However, ensuing developments led to APE’s appointment as the agent for the Byron Jackson petrochemical pump range – and, more specifically, the API 610 pump. The group is now the only manufacturer in the world to produce this series following the original OEM’s demise. “If anything, the group’s quality keeps getting better every year, with current mechanised and software solutions far surpassing the tools I had as a fledgling technician, but the principles of pump design and fluid transfer haven’t changed,” adds Kroukamp.Quality assurance

Each pump that the group produces can have up to 100 or more components that form its internal workings, particularly on multistage pumps. One missing item, and the integrity of the overall system can fail. Making sure this doesn’t happen is a core part of Themba Dlamini’s responsibilities as a quality assurance specialist, and it’s based on a solid track record of experience that dates back to 1985 when he joined the group in the main Stores Department. Over time, he received practical training in the machining workshop, and added to his skill set by attending courses in industrial marketing. “As my exposure to the business grew, I wanted to understand more about how our products fit into the market segments that we serve, as well as how they match up against the competition. That has been key in performing my role,” says Dlamini. Every pump manufactured, repaired or retrofitted by the group adheres to a sectional arrangement drawing produced by the Engineering Department, with all the parts preordered and ready. “We never assume because attention to detail is essential for guaranteed pump performance. That’s why we follow each prescribed assembly step as well as check – and double-check – that the correct procedure has been followed,” adds Dlamini.Administration

That level of attention to detail is universal throughout the group and is especially important in terms of company administration and human resource management. This area of responsibility falls under the scope of office manager, Lyn Braybrooke, who has been with the group since 2002, in the process earning Microsoft Certified Professional registration.Working directly with Peter Robinson, group CEO, her roles extend to include the compilation of tenders in conjunction with the Sales and engineering teams. She is also responsible for all inventory purchasing, as well as supporting the group’s Contracting Division from a project management perspective.

“Given our high manufacturing volumes, just-in-time delivery is the key to cost-effective production, liaising with our local foundries, suppliers and group companies globally to ensure that each pump is delivered and commissioned on time, and within budget,” says Braybrooke. “Troubleshooting comes with the territory, as does proactive internal and external communication – everyone needs to be kept informed. Foremost, though, is that if management looks after staff, they’ll look after the customer,” Braybrooke adds.

Finance

For any business, strict fiscal discipline and prudent expenditure are key to a successful enterprise. In this respect, following the money is the responsibility of Annemarie Prinsloo, as the group’s finance manager, who joined the organisation in 1997. “I’ve worked in various industry sectors, and each one has its own unique elements. This has also proven to be the case on my 26-year journey – and counting – with APE Pumps and Mather+Platt,” says Prinsloo. “Where my role really makes a difference is in ensuring that every element of our multifaceted supply chain is fully serviced from a financial management perspective. We’re Proudly South African and are committed to supporting local content and allied enterprise initiatives,” she continues. “Another key focus is continued mentorship and training, so that future leaders are empowered with accurate information to plan and budget for company expansion,” Prinsloo adds.Sales excellence

The responsibility for driving bottom-line performance needs everyone on board, says Jamie Robinson, who forms part of the Sales team, with a specific focus on the African territories where the group operates. Robinson joined the group in 2002. “I’ve been exposed to all areas of the business, which has strengthened my ability to tailor solutions for our clients. In Africa, some of our most notable projects include a turnkey system upgrade for Malawi’s Blantyre Water Board, ongoing work for the Royal eSwatini Sugar Corporation, and the supply of dewatering solutions for Zambian mining operations,”says Robinson. Within the Sales Department – and working alongside Robinson – Gabriel Ngozo is one of the veterans, and has been honing his skills since joining the group in 1984. That equates to close to 40 years of experience, which began when he joined as a receiving clerk, subsequently moving up to sales. “One thing I can say is that ensuring the highest level of customer satisfaction has always been a top priority. We pride ourselves on manufacturing world-class products, and in ensuring long-term support. Matching the right pump to the application is vital, and I’ve gained extensive knowledge in this area,” says Ngozo. “Then, from an aftersales perspective, we have a detailed record of every pump we’ve ever sold, installed and commissioned, along with all the serial numbers for every component, so, when it comes to a rebuild or replacement, the parts are always available,” adds Ngozo.