APE Pump’s global holding company – WPIL Limited – have had a busy year. They have acquired a 100% shareholding of MISA (Italy), a 100% shareholding of Eigenbau (South Africa) as well as a pending (subject to Competition Commission approval) 55% shareholding of process engineering and turnkey contracting company.

Originally established as Johnston Pumps India in 1952, WPIL Limited was founded in 1996 and has since built a strong global presence through its leading original equipment manufacturer (OEM) subsidiaries. These include Sterling Pumps (Australia), Mathers Foundry Limited (United Kingdom), Gruppo Aturia (Italy), and APE Pumps and Mather+Platt (South Africa). Specialising in the design, fabrication, commissioning, and servicing of pumps and related systems, these companies drive WPIL’s expansion across Asia, Europe, Oceania and Africa.

African footprint

Every member of the Group is a highly valued team player who contributes to the company’s collective success

“While APE Pumps was founded in 1952, WPIL acquired the entity in 2012. We have been designing, developing, manufacturing and refurbishing pumps for over seven decades – and many of these pumps are placed throughout the African continent,” says John Montgomery, the GM of APE Pumps and Mather + Platt (the Group).

Montgomery attributes the Group’s remarkable growth to its strong local presence, while capitalising on the benefits of being part of a global network. “As a South African OEM, the Group is not dependent on imports from overseas territories. Every pump component needed is made at our factory in South Africa. This creates quicker turnaround times for delivery, guaranteed quality and better customer service. Whatever the age or date of installation, APE has the ability to design, fabricate and retrofit.”

The Group has a Projects Division that takes responsibility for mechanical, electrical and civil works, and is currently graded as an 8 ME contractor by the Construction Industry Development Board. “APE Pumps is far more than an OEM, which is why we have embarked on an acquisition drive to further expand our capabilities and product range and find specialist contractors to support our project build plans,” adds Montgomery.

MISA

APE Pumps has been designing, developing, manufacturing and refurbishing pumps for over seven decades – and many of these pumps are placed throughout the African continent

WPIL Limited’s acquisitions have added to the Group’s product and service offering. For instance, they have recently acquired 100% shareholding of MISA through its subsidiary – Gruppo Aturia. MISA is a leading Italian company in the business of large pumping station projects and supply of pumps and hydro turbines and has a large reference list across Europe and North Africa. The acquisition further strengthens competencies in the supply of large pumps for water, irrigation and drainage with the addition of an excellent product range.

“MISA have a large range of axial flow pumps that are supplied for bulk water and desalination customers,” explains Montogomery.

Eigenbau

The Group has a Projects Division that takes responsibility for mechanical, electrical and civil works, and is currently graded as an 8 ME contractor by the Construction Industry Development Board. One of the many examples of successful turnkey projects was the La Mercy Pump Station

Late last year, APE Pumps finalised the acquisition of 100% shares of Eigenbau. Providing turnkey solutions for the clean water and wastewater sectors, Eigenbau has multidisciplinary project experience which includes the construction and operation of modular treatment plants.

“Their performance-driven culture, expert team, and comprehensive turnkey approach – including inhouse component fabrication – made them the ideal partner. We’ve been in discussions with their directors for several years, and we’re thrilled to have finalised the deal. The synergies and opportunities ahead are truly exciting,” says Montgomery.

Eigenbau’s experience ranges from large scale water and wastewater works, through to run of river hydro power stations where they have undertaken the challenging process of diverting rivers through to the power houses that are constructed by their staff. They currently hold a CIDB rating of 8CE (civil engineering works), 8ME (mechanical engineering works) and 7EP (electrical engineering works – infrastructure) and are a member of the South African Federation of Civil Engineering Contractor with a BBBEE grading of 3.

Investing in technology

APE Pumps is currently constructing a dedicated 3D scanning room, equipped with large screens for viewing and comparing measurements, models, and drawings

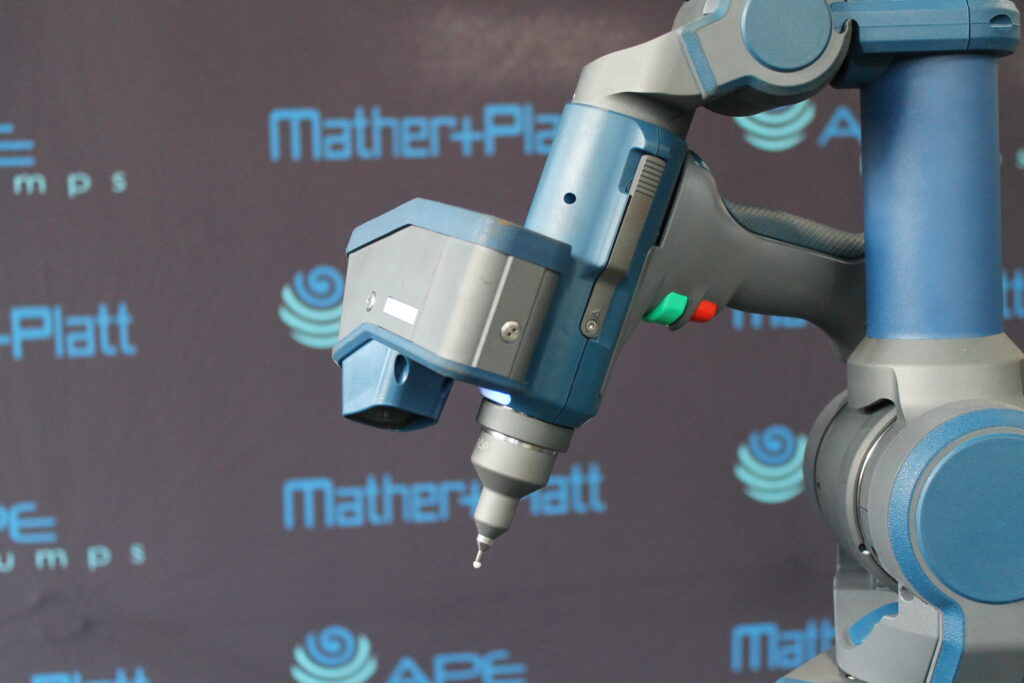

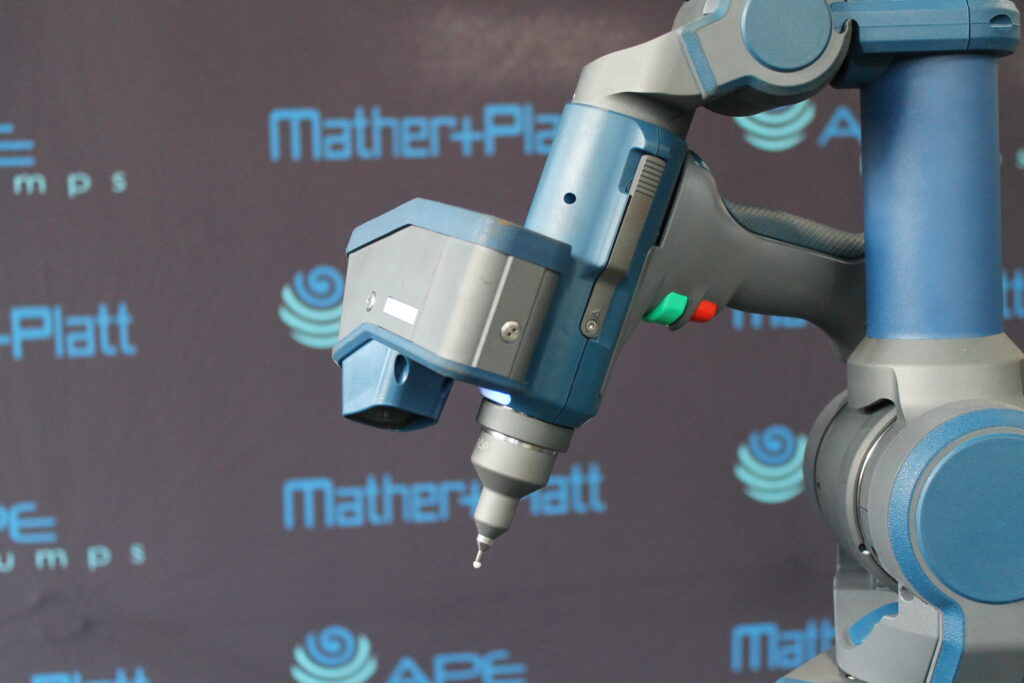

In addition to its acquisitions, APE Pumps continue to invest in technology. They have purchased a process scanner that can track the movement of all incoming and outgoing parts within their factory. This is done to improve efficiencies, identify potential bottle necks and to give customers up to date information on the status of their new pump or repair.

APE Pumps is currently constructing a dedicated 3D scanning room, equipped with large screens for viewing and comparing measurements, models, and drawings. This will serve as the primary workspace for their 3D scanner, except when it is transported to a site for on-location use.

“At APE, 3D scanning is used over and above the traditional quality control methods. It is an additional aid to prevent the misalignment of pumps by verifying pump geometries (concentricity, parallelism, perpendicularity and shaft runouts) during manufacturing, assembly and even commissioning. All pump parts (new and old) are scanned and measured, to confirm that they are to the manufacturing drawings and are feasible to reuse. The 3D scans are also used to generate digital reports indicating that the pump and pump parts meet (or do not meet) OEM specifications and tolerances. These reports are often supplied to customers. The 3D scanner can even identify a high spot on a bearing housing. Pumps can be scanned at the APE premises or on-site. APE Pumps’ investment in 3D scanning technology ensures absolute precision and innovation. We can now verify the final machined tolerances with 100% accuracy against an original design,” explains Thorne Zurfluh, a mechanical engineer at APE Pumps.

Last year, the company scanned an entire pump station using a 3D geosystem laser scanner, where the model of the pump that was to be installed was attached to the 3D point-cloud data. This put the pump in a virtual setting, and allowed APE to make sure that any interfacing issues (between newly supplied pump and existing site based and pipework) were resolved. The scanner also helped to plan how the pump would be installed. This is a value-add for clients, who do not have up-to-date as-build drawings of their pump stations.

The Group has also bought a new 3D printer that can print various pump parts in different plastics, even carbon fibre reinforced plastic. This assists with rapid prototyping, where pump designs can be easily modified without expensive tooling. Impellers, veins and casings can be optimised for better efficiencies and material waste can be reduced.

Furthermore, the company is extending it already significant factory and erecting a 30 tonne crane in addition to its two existing 10 tonne cranes in order to build and refurbish larger pumps. The working height will be up to 9 metres high. They are also building a testing bay in the near future to conduct performance tests in-house.

Other recent significant technological investments include:

- A centre lathe equipped to handle jobs ranging in lengths of up to 8 m and in varying diameters for components such as columns, shafts, and impellers (specifically for circulating water pumps)

- A key slotter for keyway cutting (a drive system feature on one of the group’s impeller-lines to enable rotation around the shaft)

- A 12-ton CNC horizontal boring machine for the final machining of larger impellers, which typically measure around 3m in diameter

- A vertical boring machine for the machining of larger components with a Ø3500

John Montgommery, GM of APE Pumps and Mather + Platt

“All of this technology must be used and operated by people. Clearly, no pump engineer, specialist technician or artisan is born overnight. The baseline skills are essential, but the experiential, applied learning is what defines master craftsmen, engineers and project managers in all our interrelated disciplines.

“That is why our business is dedicated to attracting and mentoring the best talent available. We like a two-way mentorship approach, where the old teach the young and vice versa, in modern versus tried and tested techniques. Every member of the group is a highly valued team player who contributes to our collective success. We have exceptionally high employee commitment levels, which is why so many of our staff stay with us through to retirement,” explains Montgomery.

He adds that their 100% acquisition of Eigenbau and future 55% acquisition of of process engineering and turnkey contracting company will only add to the already high level of skills within the Group. While both companies will continue to operate independently, APE Pumps will now have a phenomenal talent pool to consult when tackling challenges on behalf of their clients.

“APE Pumps is not just a pump company, we deliver end-to-end solutions that go beyond manufacturing to include design, refurbishment, and installation, ensuring long-term value for our clients,” Montgomery concludes.