Rocla has expanded its range of separators and filters for oil and petrochemical contaminants. These systems are all essential for preserving and protecting water resources as well as ensuring regulatory compliance.

Justin Kretzmar, sales engineer at Rocla

“The new products offer more flexibility and variation for designers, with cost effective units that can cater for far greater flow capacities. Additionally, we have also updated our existing range of grease separators that are specified for separation and removal of restaurant and catering industry grease,” explains Justin Kretzmar, sales engineer at Rocla.

Oil separators are commonly installed at industrial plants, urban transport areas, workshops, parking lots, petrol stations and car washes and logistics depots. When oil enters municipal water systems, it can quickly spread through sewer or stormwater networks and contaminate rivers, wetlands and groundwater. Even small amounts of oil can form a thin film on water surfaces, blocking oxygen exchange and harming aquatic life.

Additionally, oil contains toxic compounds that can persist in the environment and accumulate in the food chain, threatening both ecosystems and human health. Oil contamination presents a major challenge for water treatment plants, as it not only complicates the purification process but also significantly increases treatment costs.

Stormwater management

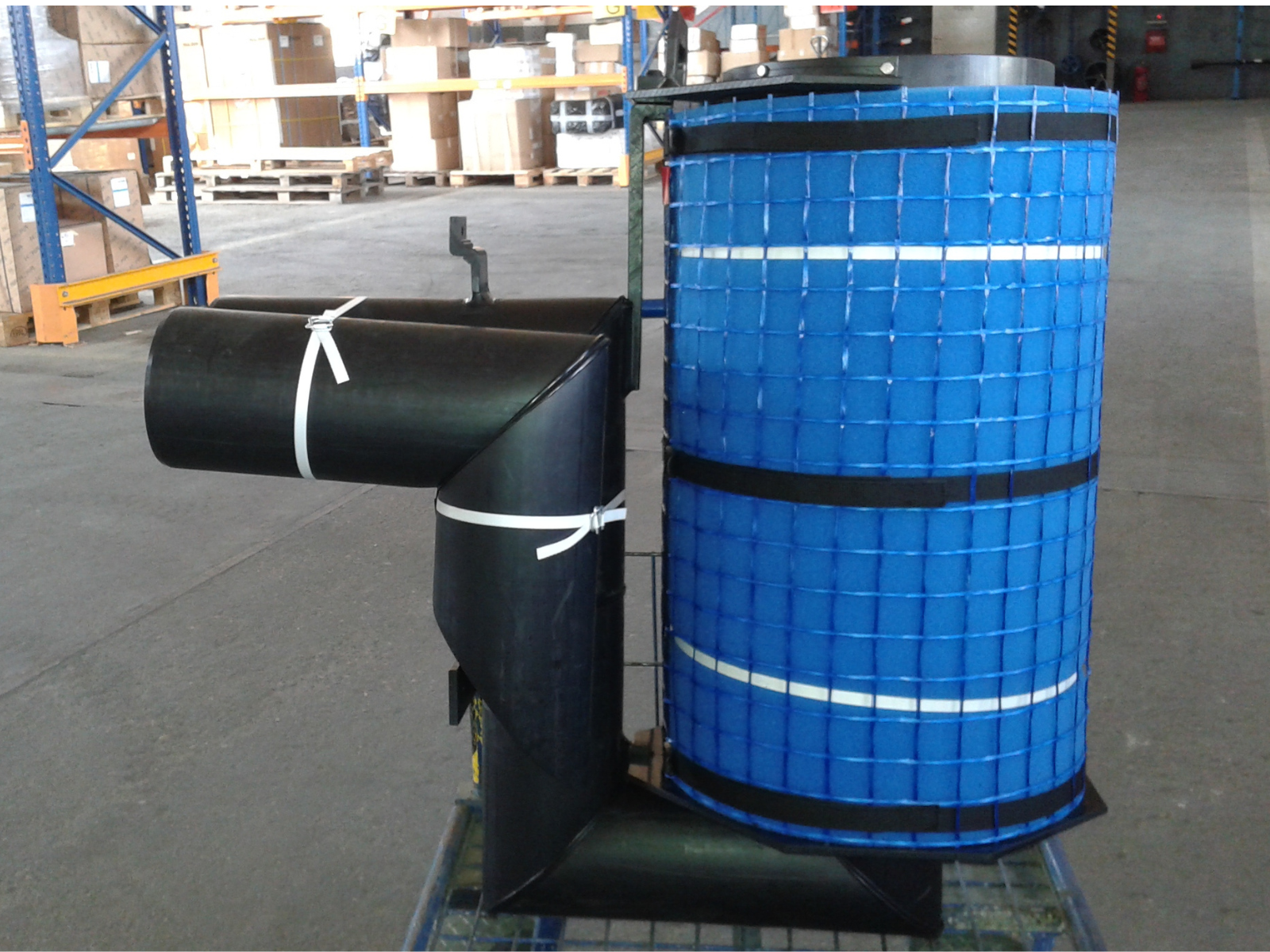

Ecol-unicon coalescing filter

“Selecting the correct type and size of oil separator for outdoor applications require careful consideration of actual stormwater volumes passing through the system. It’s essential to evaluate rainfall events and their effect on the catchment area, while also considering the location of the separator inlet – particularly whether it is positioned at the highest or lowest point on the site,” says Kretzmar.

Outdoor areas prone to oil such as uncovered workshops, truck parking areas, wash bays or fuel depots are vulnerable to stormwater.

“Our first aim is to design a system that minimises the volume of stormwater passing through the filters. It is extremely expensive to upsize an oil separator to treat stormwater that is not, essentially, contaminated. We normally isolate an area (for instance where trucks fill up with diesel) and have two stormwater drainage systems – one that diverts the clean stormwater (outside the isolated area) to a stormwater drainage system and one that diverts the dirty stormwater (inside the isolated area) to the separator and then typically sewage drainage system,” he adds.

However, there is always a risk with higher than normal stormwater flows. While engineers typically design flow rates based on a set storm event, say for example, the one-in-5-year or sometimes up to one-in-50-year flood events, these systems would not be capable of handling a one-in-100-year or greater flood events.

“In such cases, the unit can become overwhelmed, with overflow causing previously separated oil to be flushed out. To manage this risk, one would usually incorporate an additional “overflow” concrete tank upstream of the separator to handle this flow that exceeds the design conditions of the system,” states Kretzmar.

Recognising this challenge, Rocla has introduced its new Ecol-unicon ESK-B II coalescence separators, which come equipped with an internal overflow bypass to negate the need for an additional upstream concrete tank.

“These units can manage higher design flows than our current range and are hence ideal for regions like Gauteng that experience heavy, intense rainfall events. The integrated overflow bypass enables excess inflow water to skip the oil separation chamber and flow directly into the drainage system or watercourse once the design flow rate has been reached and surpassed.

“We can now design a separator to operate at a design flow rate of, say 50 litres per second, where the system will then be able to manage a storm event with a peak flow rate of up to 500 litres per second without the risk of already separated contaminants being flushed out of the system,” says Kretzmar.

He adds that it is important to note that the bypassed water, which is above the design flow rate, will not undergo treatment via the filter unit.

“The underlying principle is that the filter is designed to effectively handle the initial flush, during which the majority of contaminants are captured before the overflow is activated. The bypassed water will, for the most part, be clean.”

Another exciting product from the new range is the Ecol-unicon ESL-Z lamella separator that has multiple coalescing plates as opposed to a sponge-like coalescing media. The separation of pollutants here occurs during the multi-layer flow of water through all these plates. As with the coalescing filters, the plates used in these separators are boxed as a removable element, equipped with handles that allow them to be pulled out of the device, allowing for hassle-free maintenance.

“Like the Ecol-unicon ESK-B II, there is no risk of contaminated oil being discharged during a rainfall event up to 10 times the design flow. But the Lamella goes one step further in that it will also continue to treat the overflow volume, obviously reducing in efficiency as the flow rate increases,” states Kretzmar.

How the oil separators work

SANS 50858: separator systems for light liquids (example, oil and petrol) differentiates between class I and class II separators. Class II units are purely gravity systems rated to a maximum permissible content of residual oil in the effluent of up to 100 ppm. Class I units on the other hand, includes filter media such as coalescing filters and hence offer far greater separation, with residual oil content no greater than 5ppm.

Class I separators are designed to separate non-emulsified light liquids or low-water-soluble fluids with a specific gravity below 0.95 (such as gasoline, diesel, heating oils and other mineral oils) from effluent discharge. The two-step separation process involves a component of gravity separation but predominantly removal of the small oil particles by adsorption within the coalescing media elements.

In the separation chamber, fine droplets that are too small to be separated by gravity alone are accumulated inside the filter media into larger droplets that will then rise to the surface.

Concrete tanks

ecoTechnic ecoLine

All oil separator filters are fitted inside Rocla’s precast concrete tanks and supplied as double tank systems. The first tank being the grit/sedimentation separation chamber with the second tank constituting the oil separation chamber.

“Concrete tanks are a better long term solution to alternatives as they are stronger, more durable and provide better protection than plastic tanks, with no risk of shifting in high groundwater conditions,” says Kretzmar.

The grit/sedimentation chamber is the first line of defence, designed to settle out floatable litter and solids such as sand, gravel, silt, and other debris before the water enters the second treatment phase. This ensures that the oil separation tank does not suffer reduced operating volumes and potential damage to the filter media from abrasive particles.

SANS 50858 specifies three different size requirements for the grit tanks based on the type installation and hence expectant levels of contamination. All three sizes are available for the new range of filters except for very high flow units where the larger grit tanks are not feasible to be precast.

Maintenance

Ecol-unicon ESK-B II

“Our systems do not require electricity for operation and there are minimal moving parts – only for the float mechanism that closes the outflow valve should the maximum depth of separated oil be reached. Depending on the installation and the amount of daily/ weekly contaminant passing through the system, the coalescing filters should be removed and washed every couple of weeks or months but this is typically advised by the recyclers,” explains Kretzmar.

He adds that oil recycling companies contracted to visit a client’s site will, (after doing dipstick and visual inspections), usually recommend when maintenance is needed.

“These recyclers will drain the grit/sedimentation chamber by firstly draining the water and then removing the sludge. The oil will then be drained from the separation chamber along with the remaining water at which time the filter media will be removed, cleaned and replaced. The entire system will then be flushed until clean and then filled with water and returned to service. I always suggest that my clients have a spare coalescing media filter cartridge that can be swapped with the dirty unit which can then be cleaned and put on the shelf until the next cleaning cycle where they will be rotated once again.”

Expanded range

Rocla will continue to sell its popular ecoTechnic range of oil separators.

“They have had great success within the local mining industry as these filter units are made out of stainless steel and hence very robust. They are German manufactured products that comply not only to European standards but also to the German specification (DIN1999) that requires these filter units to have a fire rating. They are well known and respected but limited to maximum flow rates of 20 litres per second in South Africa as these are the largest tanks that we can viably precast,” says Kretzmar.

He further adds that the new Ecol-unicon range conforms to the EN858 specification with units made from HDPE, making them smaller, lighter and more financially feasible for smaller business owners of car washes, petrol stations, and transport companies.

The units are also available in a wider range and higher flow rates ranging from 1.5 litres per second up to 100 litres per second, with overflow capacities from 30 litres per second up to 1000 litres per second.

“We now have a very wide range of systems with pricing ranging from the smallest Ecol-unicon 1.5 litres per second unit at an entry level price of approximately R70 000 (excluding vat, installation and transport), ranging up to about R 700 000 for the largest ecoTechnic system.”

“We will also continue to market and recommend the ecoTechnic ADD (Automatic Draw Off Device) unit that can be fitted to any filter system. This sits inside the oil separation tank and relies on different liquid densities and a system of floats, that opens and closes its valve to automatically tap the separated oil from the surface of the tank, out the tank and into a separate receptacle that will hence be filled with only separated oils,” explains Kretzmar.

Rocla’s expanded range of oil and grease separator systems offers a comprehensive, cost-effective, and environmentally responsible solution for managing oil-contaminated runoff across a wide variety of applications. With options suited for both high- and low-flow scenarios, enhanced by intelligent design features like internal bypass systems and easy-to-maintain components, the new range empowers designers and site operators to meet stringent environmental standards while minimising long-term operational costs and risks.