Circularity forces the fast-paced and harsh business environment to slow down and foster collaboration where there previously was none. The peak of this collaborative process is industrial symbiosis, the process of having the waste of one business become a resource for another.

Industrial symbiosis involves the exchange of resources – materials, energy, water, and by-products between different industries to maximise resource efficiency and reduce waste. This network of collaboration can lead to mutual economic, social, and environmental benefits for all companies involved. While this practice is relatively new in South Africa, the concept has been developing behind the scenes for years. In 1992, at the Rio Summit, numerous countries agreed to actively find solutions to the looming environmental issues facing the globe. From this, United Nations programmes set up support mechanisms for developing nations, including cleaner production centres. This led to the establishment of the National Cleaner Production Centre, South Africa in 2002.

Tiwa Dune, a project manager for the ISP at NCPC

How does the ISP work?

In the implementation of an industrial “synergy,” the NCPC acts as a facilitator. Dune elaborates, “We play the role of an intermediary. Sectors, industries, and companies often operate in strict competition and in isolation, meaning that they may not be aware of ways they can connect with other businesses within the same sector or in competing markets. Our job is to connect these disparate elements, find synergies, and encourage sustainability along the way.” The process the NCPC goes through involves identifying waste streams as potential resources and uses a custom-built data management system to link those resources with others who can use them. Once the NCPC has identified a potential constructive collaboration, they approach companies or whole sectors to begin the process of determining the supply, the price, and logistics of the waste. They will then look for offtakers who can use the waste as a primary resource.“If the market is correct, those involved are willing, and the supply steady. We then begin the process,” says Dune.There are other factors to consider, and Dune adds, “For a business to be considered, they must be operating legally, and within regulation. If the waste is hazardous, we would need to articulate this and our part in educating and ensuring training for managing hazardous waste. The NCPC often relies on the expertise and testing infrastructure of its host, the Council for Scientific and Industrial Research (CSIR), to make informed decisions in this process.

We then negotiate with the businesses involved to reach a fair agreement between them. We are constantly monitoring the market for pricing and trends so that we can help these businesses make informed decisions.”

Aside from facilitating, the NCPC is also tasked with technical reporting. For industrial symbioses to help with sustainability, it needs to be economically viable. The reporting phase examines the data from both ends of the transaction. “As we receive data and monitor the activities, we track and report everything so that the businesses involved can see the benefit and future businesses to see the results and trust the process,” says Dune. The environmental impact of this circular practice is highly persuasive. To date, the NCPC has diverted an estimated 518 000 tonnes of waste from landfilling, thus mitigating approximately 1.7 million tonnes of greenhouse gas emissions.

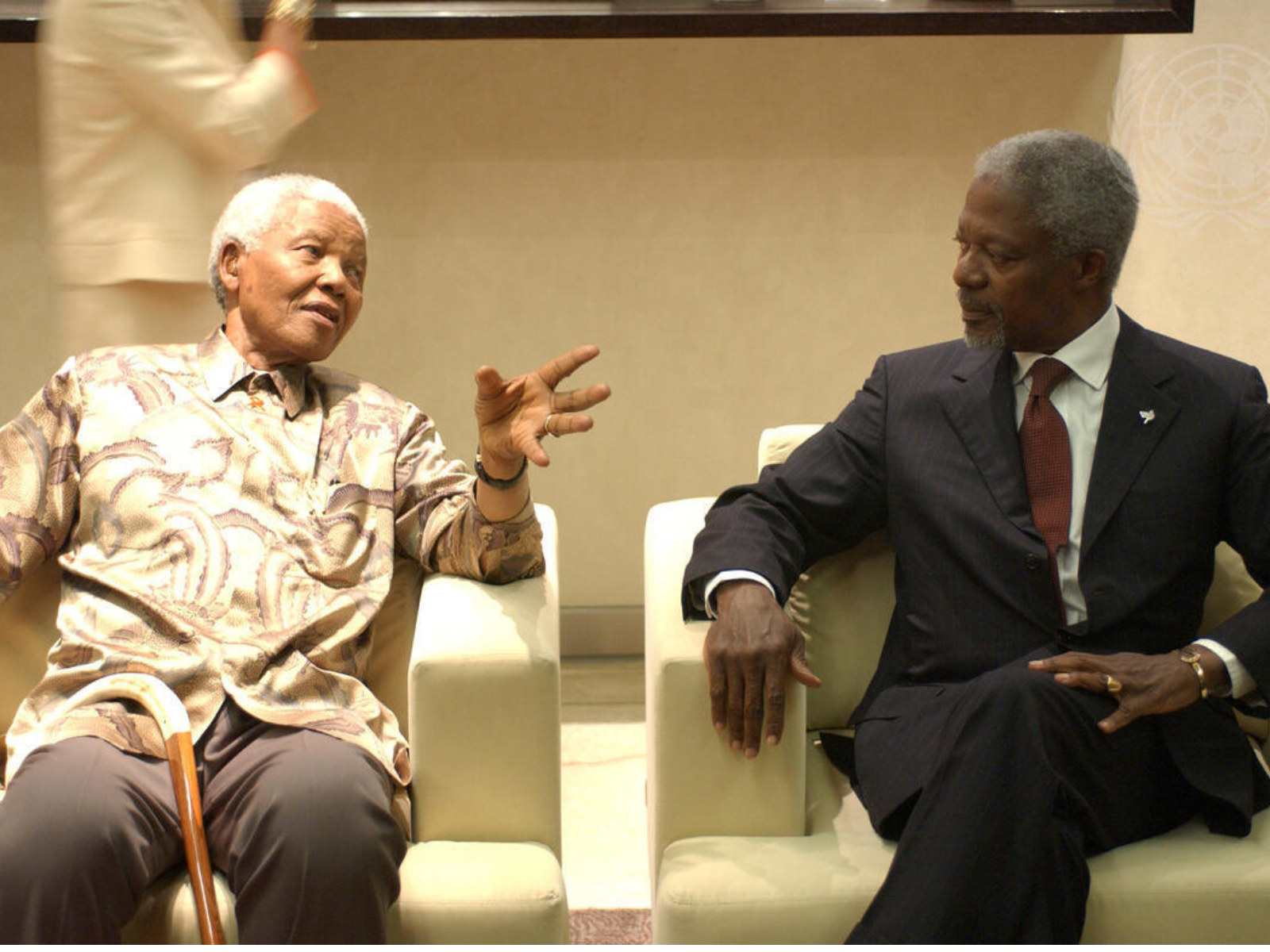

Former South African president Nelson Mandela at the 2002 World Summit on Sustainable Development which led to the opening of the NCPC

A national effort

Industrial symbiosis falls into the broader plans of the Department of Forestry, Fisheries, and Environment (DFFE), and an agreement between the two allows for the NCPC to share the reporting data with the DFFE. The NCPC is the custodian of the industrial symbiosis programmes in eight provinces, and Dune explains, “We work closely with provincial governments. They have the regional knowledge that helps us do our work. They have access to waste data and problems that may need fixing, and we rely on them for these insights. We usually approach the economic or environmental division, whichever deals with waste, and sign a memorandum of understanding. They point us in the right direction, and we then begin our process.”Circularity in progress

Organic waste is a significant byproduct of the agricultural industry, which, through industrial symbiosis, can be turned into new products

TNK Greenhouse Technology is privileged to partner with the NCPC and the CSIR, as these stakeholders are essential in developing our business professionally and maintaining quality.” Industrial symbiosis is capable of circularity in action, proving that new ways of sustainability are also economically viable.