The move toward circular business practices has led to an interest in using recycled material wherever possible. This is economically and environmentally sound, but the use of recycled material has its limits, specifically when using recycled plastics in water pipes.

The Southern African Plastic Pipe Manufacturer Association (SAPPMA) is firm that recycled plastic cannot be used in pressure pipes. Pressure pipes are used to transport drinking water, gas, and wastewater when a system cannot rely on gravity. These pipes must be able to withstand pressure for extended periods of time and be reliable in the long term – 50 years or more.

Plastic and its use have been at the centre of sustainability issues, so why is it that recycled plastic is not an answer for these circumstances?Under pressure

Peter Sejersen, technical manager of The European Plastic Pipes and Fittings Association

Jan Venter, CEO of SAPPMA

Tests using recycled plastics

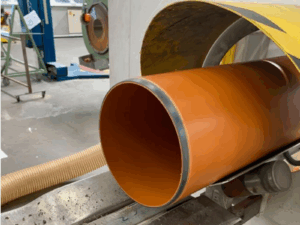

Testing a 315 mm twin wall pipe with 50% recycled material

Other pipes with varying degrees of recycled material were tested:

- 315 base, 200 mm connection pipe using 60% recycled material. One connection passed, the other failed the 1000-hour pressure test.

- PE Twin Wall, 315 mm pipe. One with 100% recycled material in the outer layer, and one with 50% in the outer layer. Both production runs failed the 1000-hour pressure test.

- PP 200 mm pipes with 45% recycled material. These failed the 1000-hour pressure test.

- PVC 200mm with 45% recycled material on the middle layer: This passed the pressure tests.

The opportunities of recycled plastic

While not suitable for pressure pipes or drinking water pipes, recycled plastic can be used in non-pressure pipes not used for drinking water. Non-pressure pipes are used for sewers, stormwater, as well as land and building drainage.“As the world embraces circularity and sustainability, there is a definite use for recycled plastics in non-pressure pipes. Our tests show the theme to be perfectly suited for this job,” says Sejersen, “it is also important to understand why we should look at recycled plastic where possible.”“The manufacturing of plastic pipes accounts for nearly half of the carbon dioxide of an entire project including installation,” says Sejersen. From this understanding, the use of recycled materials where possible becomes imperative to carbon savings. This is also where the introduction of biobased materials or chemical recycling– a process that transforms plastic to oil– can be used to mitigate the harm of plastics used in pressure pipes. “While non-pressure pipes can benefit from recycled plastics, we must still look into reducing the impact of pressure pipes by means other than traditional recycling.” In Europe, plastic production is decreasing while in Africa it is increasing. Drawing on Europe as an example, in 2022 they produced 400 Mega Tonnes (MT) of plastic, while recycling 50 MT of plastic in the same year. South Africa produces about 2,5 MT of plastic per year and recycles 430 000 tonnes (0,4) MT. Both places are comparable as Europe recycled 19% of its plastic production, and South Africa recycled 17% of its total production. This figure shows that there is room to grow, and using recycled plastics in non-pressure pipes is a step forward to reduce South Africa’s carbon impact.

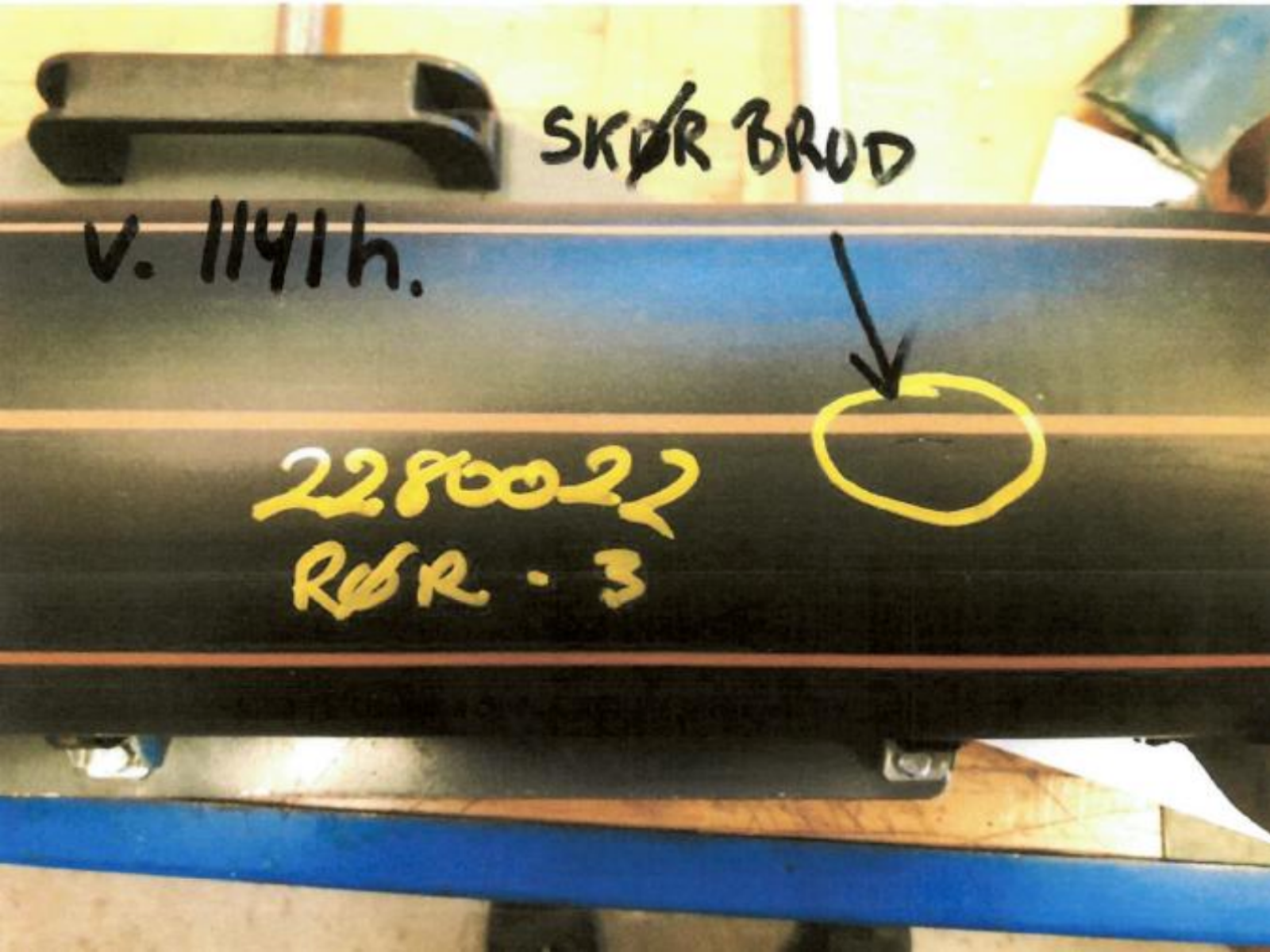

The 110mm pipe with recycled material showed a brittle failure, this illustrates that this pipe is not suitable for pressured environments.

Consequences of using recycled plastic in pressure pipes include:

- A drastically shortened operating life, resulting in unexpected and costly failures.

- Disruption of critical services due to premature pipe bursts or leaks.

- Health risks, especially when used to convey drinking water.

- Legal and reputational risks associated with transgressing standards.