Johan van den Berg, service technician, APE Pumps.

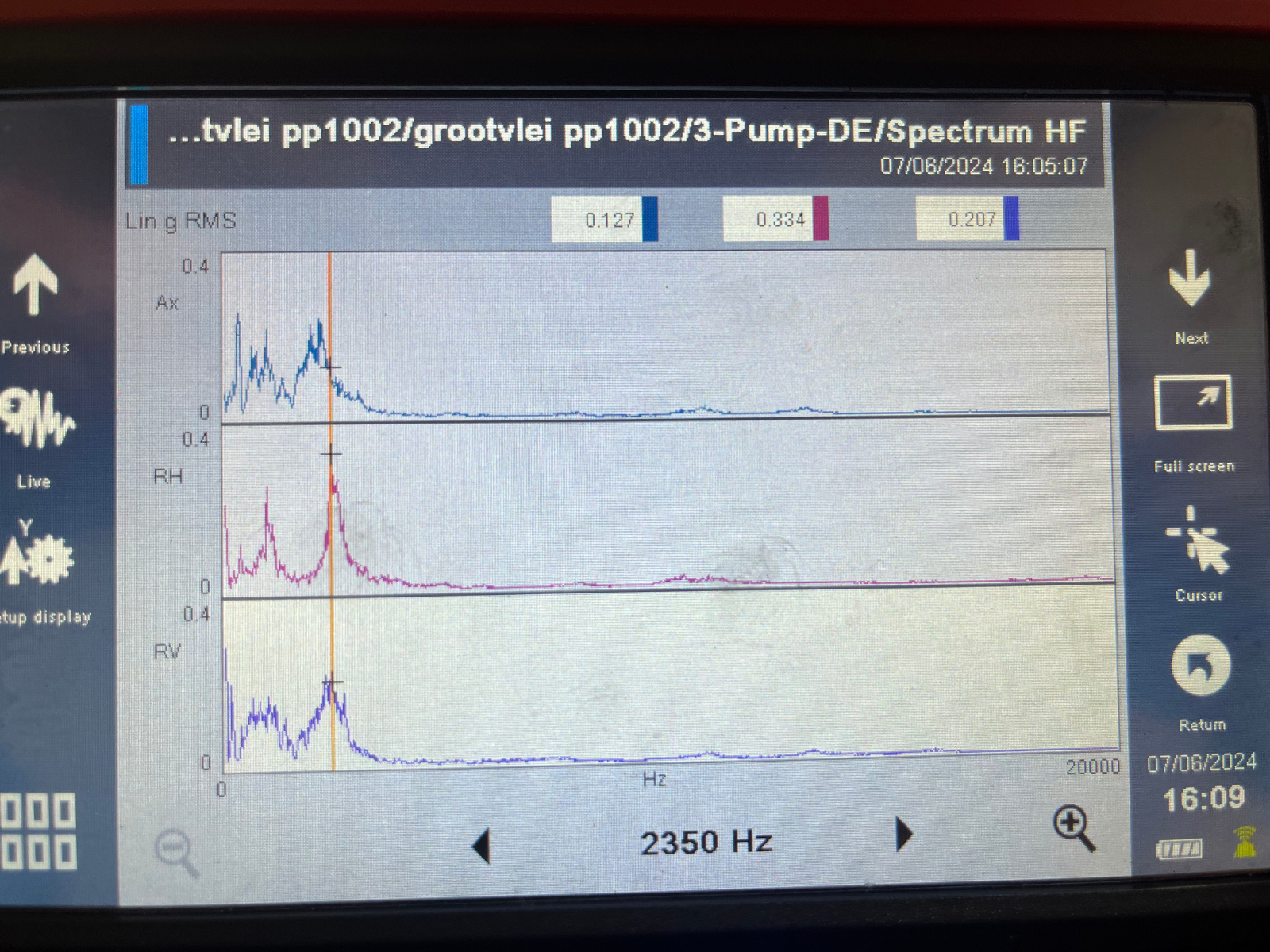

APE vibrometer measurement read-out indicating cavitation in the pump

The scope

Condition monitoring is a broad discipline. Vibration analysis and laser alignment form its backbone, supplemented by techniques such as oil sampling and ultrasonic testing when needed. Then there is the analytical or diagnostic part, which identifies the reasons behind, for example, excessive vibration or misalignment. Van den Berg has successfully passed his VCAT-2 Vibration Analysis exams, that has taught him to diagnose a wide range of fault conditions by collecting the right data and will continue to study up to the highest level – VCAT-4. Some condition assessments can be done remotely, but this is often costly, as it requires installing multiple sensors across the system along with a reliable Wi-Fi connection. “However, data alone rarely provides the full picture – site visits are still essential to understand the real conditions. Often, the most valuable insights come not from instrumentation but from conversations with the people on the ground – like the floor sweeper who notices leaks and spillages that others may ignore. Site conditions like water ingression, dust, and low reservoir levels often reveal the underlying reasons for pump inefficiency.Recognising the warning signs

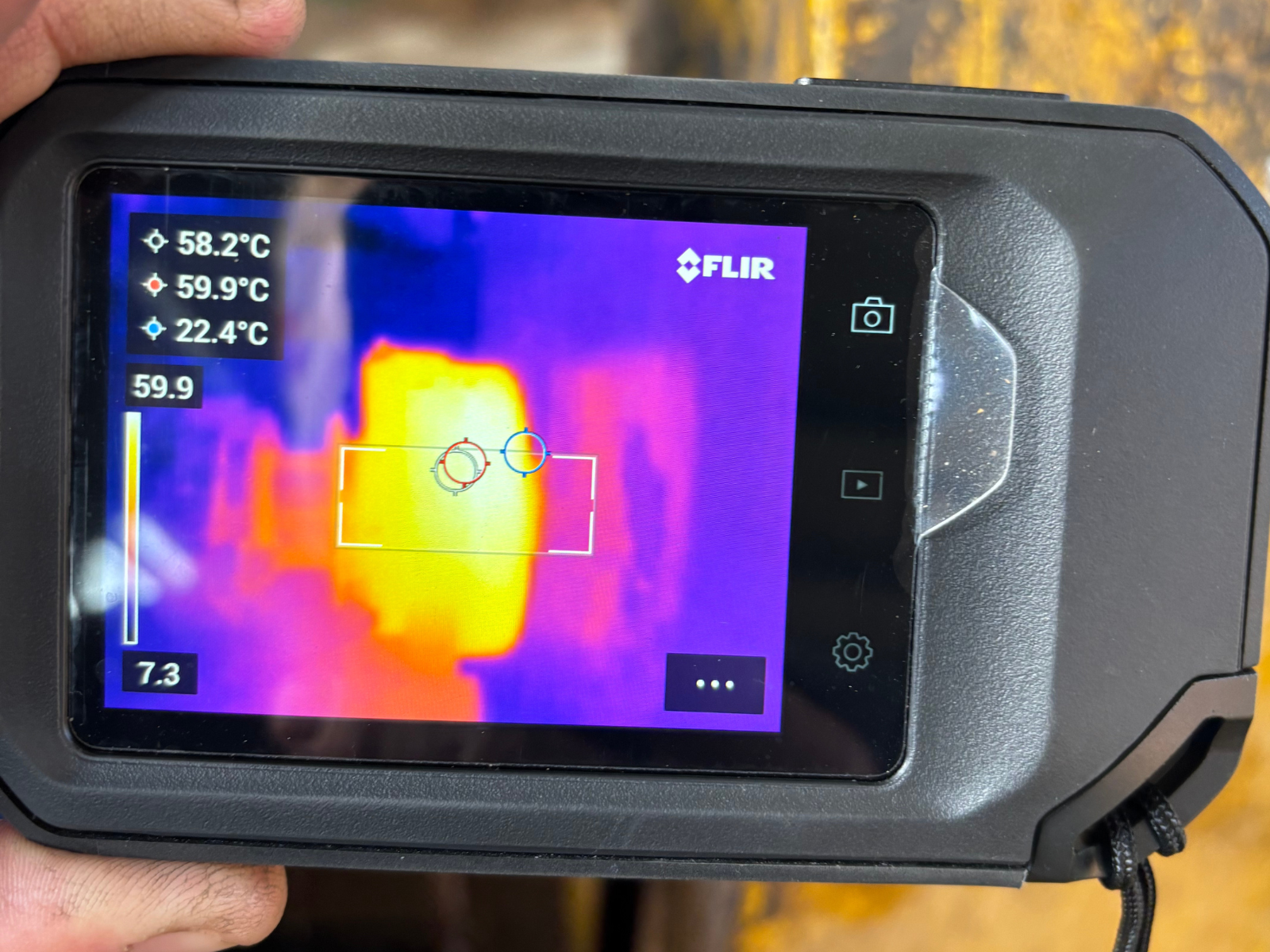

The most common red flags include excessive vibration, cavitation, and bearing failure. Cavitation, caused by restricted flow or faulty valves, produces a distinct sound—like stones rattling inside the pump. Left unchecked, it rapidly damages impellers and bearings. Over-greasing is another frequent issue, as operators attempt to prevent bearing failure but end up causing it. Temperature rises are usually a symptom rather than a cause, signalling underlying issues such as lubrication failure or cavitation. In extreme cases, seized bearings can lead to snapped shafts, damaged couplings, and even structural damage. There was an instance where a failed gearbox coupling was propelled through the roof—an incident that highlights the dangers of unchecked vibration.Tools of the trade

A valve did not regulate the water flow from a two-stage pump at a power station, causing the pump to run in overload, creating excessive cavitation inside the pump, eventually leading to a catastrophic pump failure. The picture of the vibrometer indicated the fault

“APE views it as an investment rather than a cost. Owning and operating advanced monitoring equipment enables the company to offer higher-value services,” states van den Berg.For condition monitoring, APE Pumps at times uses a flowmeter. This provides a direct measurement of the actual flow rate in the system. By comparing flow readings with pressure measurements, van den Berg can assess whether a pump is operating on its correct performance curve or if problems such as blocked valves, cavitation or other system restrictions are limiting efficiency. A portable vibration monitoring data collector is also used on any rotating equipment, as well as pressure gauges that take suction and discharge readings, so that technicians can assess the pump’s head and efficiency.

Report

Thermal radar gun checking critical component operating temperatures

“Sometimes, our customers deploy their own condition monitoring teams to conduct assessments on pumps. This then provides us with an opportunity to compare our data with their data to catch errors and ensure accuracy. Our role as an independent partner provides an additional layer of assurance,” says van den Berg.