Valves are vital in water systems, controlling flow and access, preventing backflow, as well as managing pressure. Air valves specifically release trapped air to improve pumping efficiency and admit air to avoid vacuums, protecting pipelines from collapse while safeguarding the integrity of water and wastewater systems.

Dynamic Fluid Control (DFC), a leading valve manufacturer, is committed to developing innovative solutions that address real-world challenges. One such example was in America, where heavy fines for low pressure-related sewage leaks prompted the design of a new range of valves (RGXII).Low pressure sealing valves

Jonathan Suter, research and development engineer at DFC

- Sealing at pressures as low as 7 kPa

- Improved lower float buoyancy from trapped air and increased float volume, resulting in low pressure sealing

- Shorter overall height for confined chambers

- Proven durability in sewage and wastewater environments’.

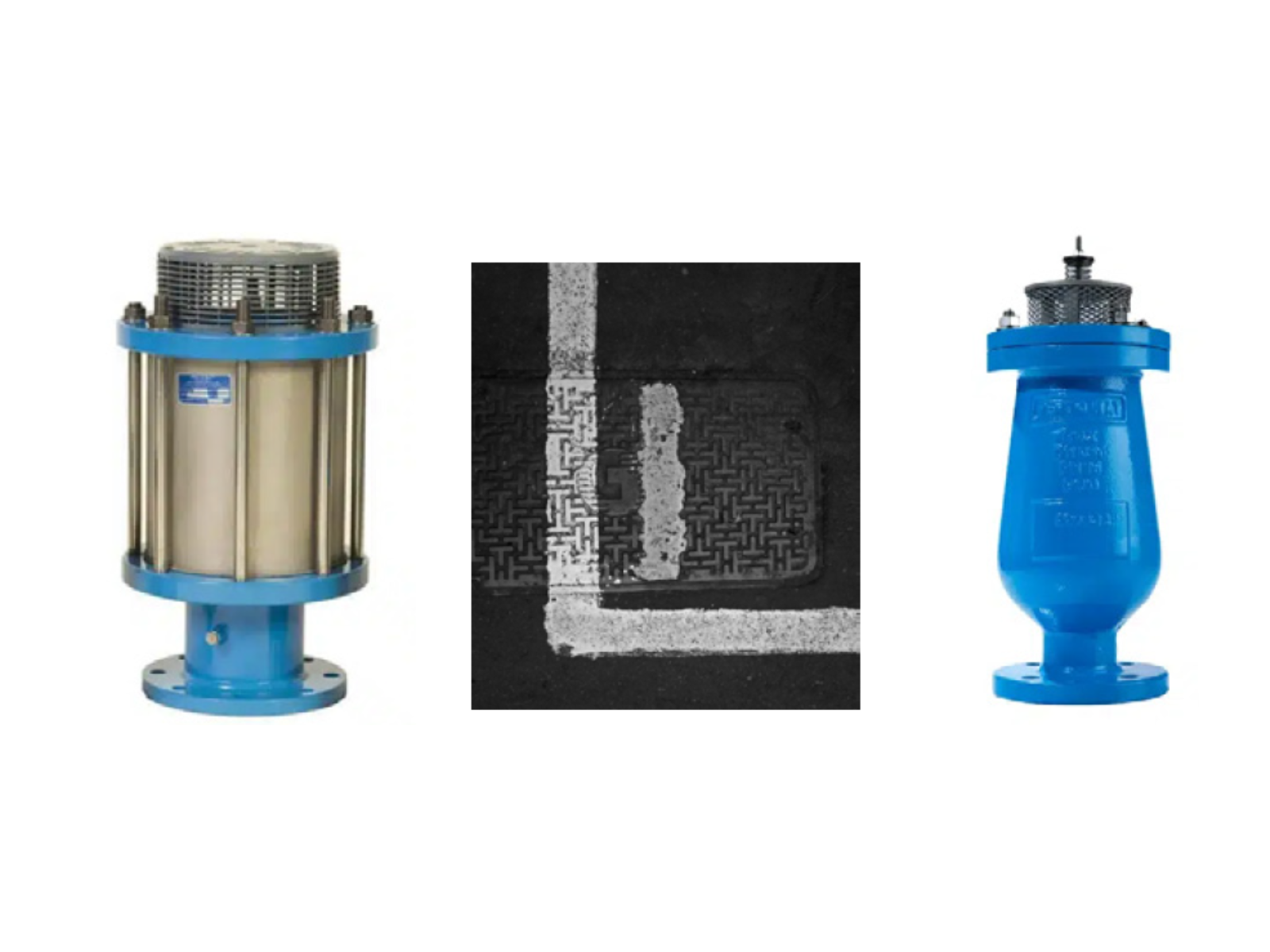

“The lower height of the RGXII valve is particularly useful in underground closed valve chambers where chamber cover height restrictions are imposed. Its unique float cage allows for easy float extraction maintenance,” explains Suter.Furthermore, the anti-surge float technology is a pressure spike alleviation mechanism that protects the pipeline in the event of sudden air valve closure. The anti-surge or anti shock float does not fully close or slam shut when a sudden rush of fluid and air comes through the pipeline. The air valve continues to vent air through the small orifice while creating an air cushioned accumulator or gas spring that decelerates the fast-approaching fluid over a longer distance. It also ensures that the fast-moving liquid does not come to a sudden stop.

Feedback from real-world application

In South Africa, Siza Water, a water utility in KwaZulu-Natal, received the RGXII as part of their operations and report that, “Before partnering with DFC, we encountered challenges related to air accumulation in pipelines–leading to inefficiencies, pressure fluctuations, and increased strain on critical infrastructure. Traditional air valves required frequent maintenance and were prone to premature failure, causing operational disruptions. From installation there has been 60% less interventions in terms of maintenance in 3 months, and the valves’ 15-year lifespan puts Siza Water at ease.Other valve applications

As the RGXII is designed for sewer applications, Isaac Mahlangu, technical analyst at DFC adds that for potable water applications, the company offers the RBX and RBXc (ast body) valves.“The RBX comes in a variety of materials, including stainless steel grades 304 and 316, duplex, super duplex, and materials suitable for seawater or brine applications.”Irrigation systems utilise RC and RPS valves, with the former featuring a cast iron body and the latter made from nylon 6 plastic, tailored for durability in diverse environments.

The problem with air

Isaac Mahlangu, technical analyst at DFC

CATT Program

To assist engineers and designers, DFC has developed the Controlled Air Transfer Technology (CATT) software, a free, globally accessible program for precise valve sizing and placement. After registering, users input pipeline coordinates, fluid type, flow parameters, and pipe material into the software. The program analyses the data and recommends optimal valve locations, considering critical factors such as the hydraulic gradient line, which affects valve function and prevents siphoning. Users can also manually input scour and isolation valves to tailor the system further. “The software allows you to optimise your valve placement and produces detailed reports, including economic assessments and pipeline profiles,” the representative explains.“Valves may look simple,” concludes Mahlangu, “but their design and placement are critical to keeping pipelines efficient, reliable, and protected from damage. That is why, beyond manufacturing and designing valves, DFC also provides technical support, valve repair, site audits, and training.”