Plastic remains a top priority for South Africa’s recycling initiatives. Polyethylene terephthalate (PET) is a highly recyclable plastic and is the material of choice for plastic bottles.

The process of PET recycling varies, but usually follows collection, sorting, cleaning, shredding, melting into pellets, and for food-grade PET, the recycled material is sometimes crystallised and re-polymerised to restore molecular weight and strength. Starlinger, a machinery company, has been involved with plastic recycling technology for 35 years, with a mission to make recycled plastic a viable alternative to virgin material. Starlinger recycling plants are used across the world, and many organisations in South Africa, like Alpla Recycling, Atlantic Plastic Recycling, and Extrupet. For Starlinger, PET beverage bottle recycling represents a closed-packaging cycle.Bottle-to-bottle recycling

Paul Niedl, commercial head at Starlinger recycling technology

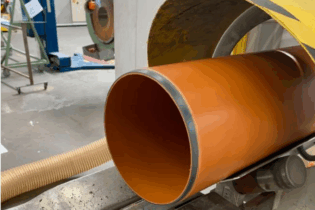

The recoSTAR PET art recycling line is the company’s latest model in the field of PET recycling. This model builds upon Starlingers’ established decontamination performance for food-grade applications and high-quality pellets by introducing a lower energy consumption unit with simplified maintenance processes.

Paul Niedl, commercial head at Starlinger recycling technology, compares the bottle-to-bottle recycling process to high art, he says, “It is a composition, a synthesis of experience combined with the latest scientific knowledge and high technological standards. The new recoSTAR PET art embodies more than 20 years of experience in the field of PET food-contact recycling. In addition, technical improvements have been made to make the plant easier to maintain and even more energy-efficient.” For Starlinger, this new system represents the culmination of ideals, specifically designing the recycling process to be as energy-saving and efficient as possible. The PET bottle-to-bottle recycling system recoSTAR PET art uses 25% less energy than the previous model, and requires 46% less maintenance time, has a 21% smaller machine footprint, and an increased output of 15%. In total, bottle-to-bottle recyclers saves approximately 21% in production costs with the new system. One of the main changes in the new PET recycling system is the combination of two separate drying units with a residence time of one hour each into a larger unit with a residence time of two hours. Additionally, this model doesn’t require vacuum degassing. Both of these innovations contribute to the reduction of energy consumption and reduced maintenance requirements. Additionally, the European Food Safety Authority (EFSA) has confirmed that the system complies with its decontamination standards.Niedl explains, “This machine is the culmination of years of experience. Decreasing energy consumption while increasing output and ensuring easier maintenance involved analsying the entire PET recycling process and our technical solutions, finding ways to make both better at every point.”