He added that this standby configuration would also ensure that if either pump malfunctions or requires servicing, it would give the pumping station a four to eight hour buffer period before it would breakdown or overflow.

However, these pumps would continue to operate in the case of overflow due to their submersible designs. During early stages of the installation, a temporary T8 pump was installed to ensure that no effluent would be discharged, and so sewage would continue to be pumped into the wastewater plant.

An overloaded sewerage system is no longer causing a stink in Newscastle, KwaZulu-Natal.

The outdated Ncandu pump station, situated five kilometres from the town, was unable to meet high sewage capacities. This left the municipality and downstream industrial businesses with an overloaded sewerage system.

The old pumps were replaced by Veolia Water Technologies South Africa. The company said that the pumps were prone to tripping and often flooded the pump station.

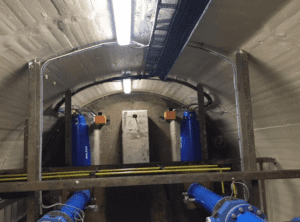

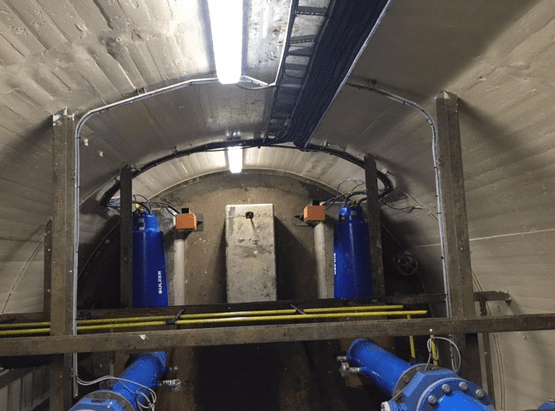

The station was first cleaned out, 15 metres below ground. This included removing sump, scraping the walls and rehabilitating the existing infrastructure for the new, larger pumps.

The old pumps were replaced with two new Sulzer pumps, imported from Germany, and were integrated into the existing pipe infrastructure.

Veolia said that both Sulzer XFP high-capacity sump pumps are capable of processing 220 litres of raw sewage per second at a 27 metre elevation.

Project engineer Blake Cooley said that the pumps were set at a standby duty configuration to ensure system reliability. “This means that when the first pump reaches 60% capacity, the second pump will automatically switch-on to ensure demand is met and that no flooding or overflow discharge occurs,” he said.