The Tongaat Water Treatment Works (TWTW) was one of the hardest hit pieces of water and sanitation infrastructure in last year’s April floods in KwaZulu-Natal. It resulted in water supply issues for nearly 90 000 people.

By Kirsten Kelly

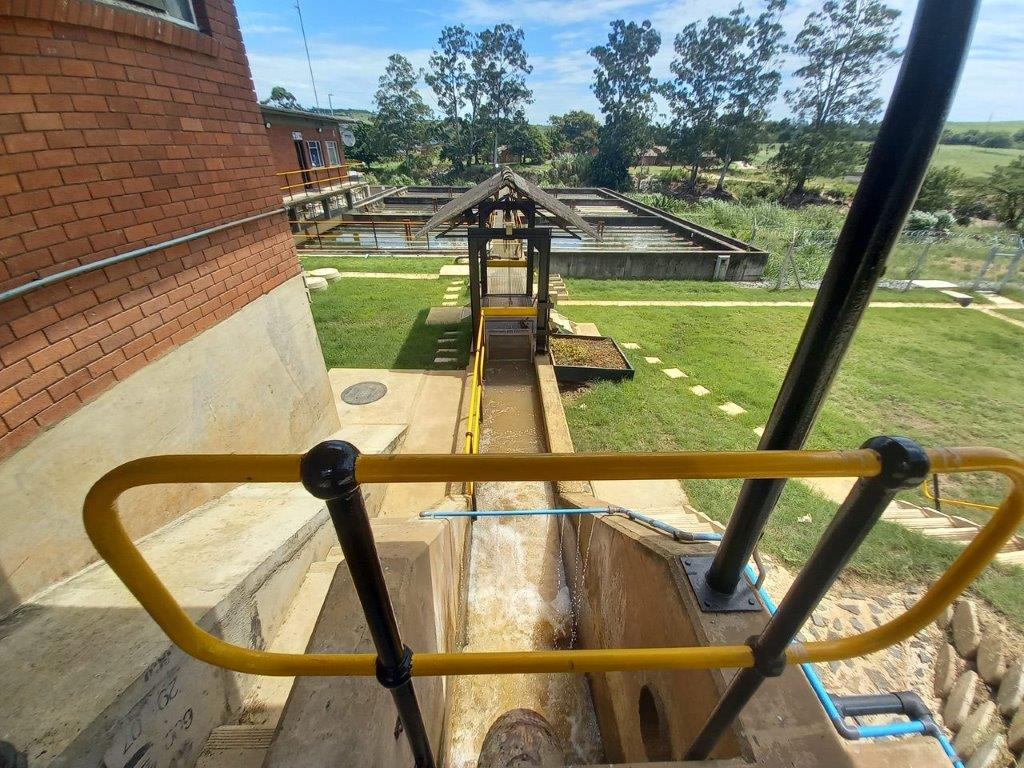

- The motor control centre (MCC) was located underground within the pump house, and both were submerged in nearly 4 m of water – destroying all electrical equipment and damaging mechanical systems like the pumps, motors, instrumentation and control systems.

- A lot of silt and rocks were found in the clarifiers and some of them were severely damaged.

- The head of works channel was significantly damaged and founding material washed away. This channel settled and required significant repairs, including being jacked back into position.

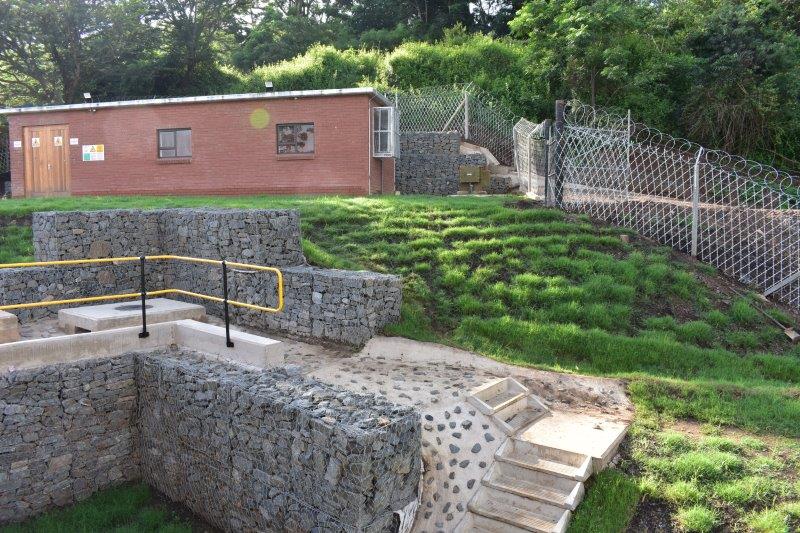

- The floods also caused substantial erosion, resulting in the undermining of the chemical and chlorine building foundations.

- Most interconnecting pipework, cabling and ducting on-site was damaged.

- Fast-track the tie-in of the Mamba Ridge pipeline from the Hazelmere Waterworks to the Mamba Ridge Reservoir. Once completed, this resulted in directing 2 Mℓ of water a day from the Hazelmere Water Treatment Plant to some parts of oThongathi.

- Supplying water from the Belvedere Reservoir (cross connection to Hazelmere System).

- Laying a water main to the Tongaat South Reservoir from the Nyaninga Reservoir, using eThekwini Municipality’s in-house construction team as far as possible in order to bypass the lengthy procurement process.

Professional team

Section 36 of the Municipal Supply Chain Management Regulations was invoked to speed up the procurement process and acquire funding. Section 36 falls within the Municipal Finance Management Act (No. 56 of 2003), to select who will carry out a particular contract. eThekwini used a quotation process and a Naidu Consulting/MSW Consulting joint venture appointed as the consultant, Icon Construction was appointed as the contractor, with PCI Africa as a subcontractor for the mechanical, electrical, instrumentation, automation and control work. The Naidu Consulting/MSW JV did the initial damage assessments and produced multiple options to ensure the restoration of the water supply to the Tongaat area. “We also did a full assessment to determine a baseline for the work that needed to be undertaken to restore the plant to operation, including assessing various approaches to the remediation woks and produced the applicable emergency tender documentation for this contract,” states Devesh Ramghulam, technologist, Naidu Consulting.

105 days

“The repair of the TWTW was completed within the agreed upon 15 weeks or 105 days (from 13July to 27October 2022). To put this into perspective, 9 to 12 months would have been an ordinary contract period for this volume of work. The TWTW repair project ran on the tightest schedule Icon Construction has ever had. Fortunately, we had an extremely competent professional team that worked on the project,” says Peter Hope, commercial manager, Icon Construction. All investigative work from the Naidu Consulting/MSW Consulting JV was completed days after the flood. Ramghulam adds that everyone (client, consulting engineers, contractor and subcontractors) was available 24/7 to ensure the works were completed on time. “Naidu Consulting placed a full-time design engineer (Devesh Ramghulam) and resident engineer (Neelesh Hira) on-site with process support from MSW Consulting. The client also provided a dedicated, full-time project vmanager (Shalina Ramnund) to fast-track eThekwini approvals and decisions. The entire professional team held weekly meetings to identify project bottlenecks, assess availability of equipment and determine on-the-spot resolutions.” PCI Africa had the expertise to design and execute all the mechanical, electrical, control and instrumentation work in-house. This made meeting the extremely tight deadline possible, despite some external difficulties. “Globally, the world has been grappling with serious supply chain delivery delays. It is impossible to import PLCs, communication cards and general automation equipment in short time frames. This is caused by the closure of Chinese ports and factories due to Covid-19 restrictions and the Russia/Ukraine war,” explains Lebo Rathebe, proposal manager, PCI Africa. “To counter this, our in-house electrical and instrumentation design capacity allowed us to remain flexible. We were able to design around equipment that is available, meaning we can present a design that is uncompromising, yet still achievable. Our extensive network allowed us to call on suppliers for assistance and, when coupled with our good relationship with EWS, we were able to acquire all the hardware that was required,” adds Desmond Kopke, electrical engineering manager at PCI Africa. “Everyone on-site had a mindset and goal to deliver water to the people of Tongaat within the 105-day contract period. We received an extensive amount of support from the Tongaat community and this played a significant role in avoiding project delays,” says Ramghulam. Hope states that while the project had a high level of political involvement, where the mayor and senior officials from the Department of Water and Sanitation visited the site often, no one hindered the project’s progress.Repair

“While Tongaat Hulett no longer owns the TWTW, a substantial amount of damage was caused to its own water infrastructure and it has been a huge support in the restoration of the TWTW. In addition to repairing the access road and raw water pipeline, the company allowed a part of the new MCC to be built on its land,” explains Soni.

Designs on foundations of the chemical and chlorine building, as well as the inlet pipe and underpinning, were completed on-site to ensure structures were safe, accessible and suitable for future use. This was done in short timeframes to enable access to other areas of the site. “Due to the nature of the ground conditions and surrounding buildings, heavy vibratory equipment could not be used beneath structures, and therefore applicable concrete underpinning was implemented,” explains Ramghulam.

Building back better

Commissioning

Before commissioning the TWTW, all five reservoirs were inspected, cleaned, disinfected and the water quality was tested. Since the entire system had not been in operation for months, it was therefore expected that there would be multiple pipe bursts once the TWTW was commissioned. However, this did impede efforts to build capacity in the reservoirs. One trunk main and reservoir was commissioned at a time so that the EWS team could focus on a particular zone and immediately resolve any issues that may arise.

Phase 2

Originally designed for 21 Mℓ/day, the TWTW is currently operating at 14 Mℓ/day. The Naidu Consulting/MSW JV has been appointed to design the TWTW’s functional upgrade. Currently, EWS has limited abstraction rights from the Tongaat Dam, which restricts the plant’s capacity. An agreement will need to be reached between the Department of Water and Sanitation, Tongaat Hulett and EWS to determine the maximum amount of water that can be abstracted for Phase 2 of the TWTW functional upgrade. Phase 2 will include upgrading the inlet channel, trunk mains and pumps in order to cater for future demand. The head of the works will be upgraded to give better assurances of water quality and how water is channelled to clarifiers and filters. “While we would have liked to have included this work in the actual repair project of TWTW, we were heavily focused on restoring water supply to the local communities as quickly as possible,” states Soni.

Conclusion

Soni adds that while EWS has experience and expertise in the day-to-day operations of water and sanitation systems, the floods were an unusual event and the municipality was not fully equipped to deal with a disaster of that magnitude. “Going forward, there should be a national disaster management team that has already appointed contractors and consultants as well as funding in place to handle these disasters. If something like this were in place, a lot of the restoration work would have been completed more rapidly. The biggest delay in responding to disasters is a procurement process, and a national disaster management team and our own in-house construction teams can assist with quicker response times.” “This project is an example of what can be achieved if all project stakeholders work towards a common goal, in this case resulting in achieving the near impossible – the restoration of a treatment plant within 105 days,” explains Ramghulam. He adds that supplying the community of Tongaat with water after almost eight months without it was something the Naidu Consulting team will never forget. “We are glad to be able to have assisted on this feat of engineering.” The repair of the TWTW was Hope’s last project before he entered retirement. “While this was a relatively small project (totalling R48 million) when compared to other work that I have been involved in, it was a great last job for me personally, because of its huge impact on people’s lives. The team working on the project were exceptional and the high attendance record and commitment shown on-site by the workforce made the job that much easier.”