Peter Hardie, manager technical and international sales, AKS Lining Systems

Textured linings

“The addition of a textured surface allows the design engineers superior performance options when looking at side slope lining, slope stability and other design criteria,” says Hardie. AKS Linings offers a Micro/Mega product range that is manufactured with a high ‘asperity’ or spike on one side and a smaller asperity on the other side. These spikes are less than 1.1 mm on the bottom side and less than 0.65 mm on the top side. This gives design engineers the ability to create a preferential slip interface within the lining system. The larger asperity will offer a higher friction to the subgrade or soil than the small asperity offers to the top layer. Therefore, if there is any settlement inside the lined structure, due to waste being compacted or for any reason, the slip will occur on the top side of the liner, meaning that a liner or barrier system remains in place, protecting and containing the waste.

Linear Low-Density Polyethene (LLDPE)

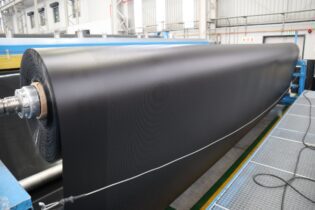

AKS Lining Systems has recently produced a range of LLDPE liners for a local landfill site. LLDPE or Linear Low-Density Polyethene is a more flexible liner and when used in the right application, offers a few benefits over conventional HDPE.

AKS Lining Systems has recently produced a range of LLDPE liners for a local landfill site. LLDPE or Linear Low-Density Polyethene is a more flexible liner and when used in the right application, offers a few benefits over conventional HDPE.

Hardie explains, “On our co-extrusion machines, we are also supplying what is referred to as a ‘reflective liner’. This is a liner which is extruded with a thin, light-colored surface on the top exposed side. This assists with reflecting sunlight and heat during the installation process and allows the liner to lie flatter, to assist with the placement of cover soil and protection layers.”When linings are deployed on site, it is important to monitor each liner, and AKS rolls are individually labelled and numbered. The in-house manufacturing quality control system ensures traceability of each roll and its components right through from the incoming resin to the in-line production testing, quality control testing and final manufacturing quality control certification. Being ISO 9001:2015 certified ensures that management systems and quality procedures are maintained and reviewed at the highest possible levels. These systems and procedures follow through right from resin suppliers, shipping and logistics to finished product, testing and delivery.