A potentially complex engineering feasibility study has been simplified with the use of Autodesk Software.

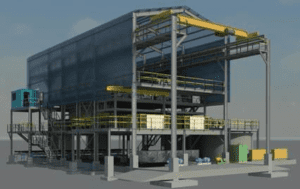

Environmental and Process Technologies (ENPROTEC) was recently tasked with conducting the feasibility study for a new ultra-fine coal flotation and filtration plant. ENPROTEC was established based on the need in the market for a mineral processing company with the capability to provide solutions for the recovery of ultra-fine coal material, says Nadia Scapin, Project Manager for planning and administration. “We pride ourselves on our knowledge and experience to provide sustainable and viable solutions to our clients. We have the in-house capability to carry out environmental, economic and technical feasibility studies to determine the most viable solution to turn waste streams into viable product streams.” This was ENPROTEC’s first project utilising Autodesk Revit. With the implementation, training and support they received from Prokon Software Consultants, they were able to meet the demands required for the feasibility study. The business needed to conduct a detailed feasibility study for a coal flotation and filtration plant, while incorporating several sets of changes from participating stakeholders.Autodesk Revit in conjunction with Prokon software was used to conduct the feasibility of the initial layout of the structure. They were able to design plant walkthroughs in 3D, which allowed them to optimise and change the design to allow for easy access and maintenance, as well as reducing unnecessary steelwork.

Autodesk Revit was also used to generate the general layout and assembly drawings, as well as the structural design drawings. ENPROTEC also used Autodesk AutoCAD for the layout on the block plan of the plant, as well as the generation of the process flow diagram. Visualising the feasibility of the project allowed for ENPROTEC to put plans in place for their unique green features. “The proposed green features discussed in the feasibility study include our unique flotation and filtration technology that eliminates the requirement for slurry dams which turns previous waste streams into revenue generating product streams and, in turn, drastically reduces the water usage of the mine. Through using Autodesk Revit, ENPROTEC was able to reduce the carbon footprint of the structure.” Autodesk software also assisted in addressing some of the challenges of the project. “We faced multiple changes during the feasibility study. Autodesk Revit allows for quick changes in structures so we were able to make multiple changes to explore the different options in partnership with the client within a very limited time,” says Scapin.