The difference between a circular economy and a recycling economy, and why we should care

By Hermann Erdman, CEO of REDISA (Recycling and Economic Development Initiative of South Africa) Our dominant linear ‘take-make-consume-dispose’ economy is unsustainable. Dwindling natural resources and growing demand are inescapable: it is only a matter of time – in some cases just decades – before certain resources will no longer be available as virgin commodities. Towards a circular economy Circular economy thinking moves away from waste: it looks at preventing the waste rather than managing it. The recycling economy on the other hand focusses on recycling waste so that it doesn’t end up in landfills, but is reliant on waste in order to survive. So which is the best approach to tackle the severe environmental and socio-economic issues we face, and drive much needed new industry development while ensuring that manufacturer’s bottom line goals are achieved? In a recycling economy, little attention is paid to the manufacturing or design stage. Currently huge amounts of energy is used when making products from raw materials. However, as long as the recycling process is independent of the design stage, it cannot address the long term challenge of incentivising manufacturers to change their processes. This would mean using less raw material, reducing energy use and making products that have a reduced negative impact on the environment. The circular economy promotes a sustainable industry where product design is influenced in a manner that makes not only environmental sense, but also business sense for manufacturers.Incentives for change

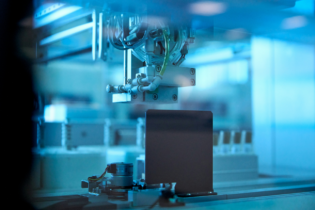

The main difference between the circular economy and the recycling economy is that manufacturers are incentivised to change and develop better design processes. This is becoming a reality in South Africa through an approach that was lauded by the World Economic Forum in Davos in 2016 as a successful model. In South Africa, through legislation and regulation the tyre industry has ensured that tyres, severely damaging to the environment, do not become waste at the end of life. In line with promoting a circular economy ultimately manufacturers will be incentivised to shift their product’s design to cradle-to-cradle manufacturing techniques. Product testing institute launch REDISA is funding a Product Testing Institute to be completed by 2017 which will provide an environmental rating system. The rating system will promote the development of tyres that, when considered over their entire lifetime from manufacture to end of life disposal or recycling, have minimal environmental impact. These tyres will of course be able to be recycled, but the focus goes far beyond only recycling. A better product will obtain a better environmental rating from the Institute, and this in turn will mean that manufacturers pay a lower waste management fee to extended producer responsibility organisations like REDISA. Those products that obtain a poorer environmental rating will pay higher fees – thereby driving the shift to greater sustainability in the South African economy. For the first time in an industry, 100% of tyre manufacturers and importers in South Africa are taking responsibility for their waste by passing the responsibility to an organisation like REDISA, which is ensuring that the environmental disaster that waste tyres represent is being economically and effectively addressed. This is the springboard for implementing circular economy principles in the tyre industry. Conclusion At REDISA we recognise the possibilities that lie in circular economies, specifically for all those willing to look at waste not as waste, but as a commodity. Through this approach, items that would otherwise be disposed of as waste can be reused, in whole or in part, multiple times. This restorative system extracts the maximum value out of a resource, ensuring that products have endless lives.