South Africans generate roughly 108 million tonnes of waste per year. Only 10% is recycled and the rest ends up deposited across our landfill sites. ReSource speaks to Henri Thompson, group executive chairman at the Somerset Group, about the company’s introduction of a revolutionary technology to address this.

South Africa’s landfill sites are not only fast approaching full capacity, but the piling-up of waste is causing tremendous land and air pollution. A 2020 study has also shown that communities who live close to landfill sites (within 5 km) are at a 41% higher risk of developing asthma, an 18% higher risk of developing tuberculosis, a 25% higher chance of having diabetes, and an 8% greater chance of suffering from depression. However, with government’s renewed focus on transitioning towards a circular economy – with the revision of the National Waste Management Strategy (2020) and approving key actions that will contribute to climate change, emissions reduction and waste minimisation – many businesses are looking for more sustainable ways to deal with their waste. For the longest time, there seemed to be no feasible solution in sight but Somerset Group’s Asher promises to deliver not only a sustainable waste management solution but also a cost-effective one. Somerset Group is a multifaceted company with a special focus on international trade and infrastructure projects. It specialises in all things renewable energy, water and lighting. Since its inception in 2012, the business has grown into a multidisciplinary organisation that has developed extensive skills and resources in green technology.The Asher

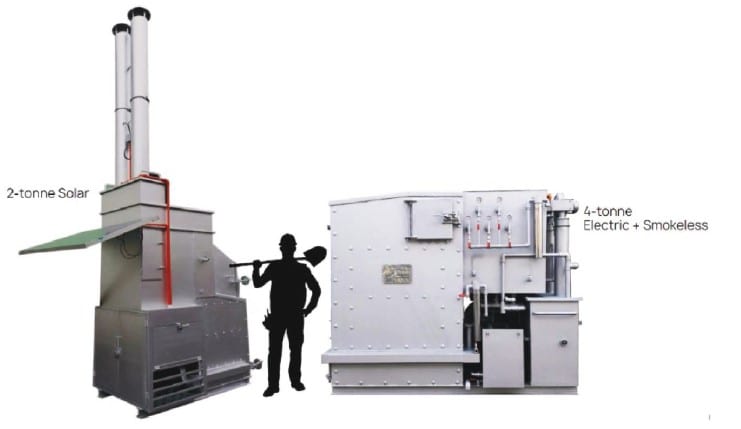

Upon signing an agreement with Keelinx SDN BHD, the authorised representative of Pamarai (the Asher’s global exclusive distributor, trademark owner and manufacturing partner) for Africa, Somerset was tasked with bringing Pamarai’s proprietary Asher technology to local and regional markets. The Asher is a zero-waste machine that can quite literally ‘bake’ waste into multipurpose ash without polluting the environment – effectively solving the problems associated with landfills and incinerators. Thompson says Somerset went through various legal frameworks to ensure that the Asher was legal and within the specifications of the countries it’s expected to operate in, largely because it is designed to comply with US EPA standards. In Malaysia, the Asher’s birth country, it has received its MyHIJAU Mark certificate, a green label awarded by the Malaysian Green Technology Corporation, a government agency under the Ministry of Environment and Water of Malaysia. The green label was given after scrutinising its performance, safety, environmental impact and design aspects. It is also in the process of being certified with the National Environmental Management: Waste Act (No. 59 of 2008). The first prototype was created in 2010 by Roland Tee, a retired Malaysian auditor. He realised, from reading newspapers, that there needed to be a more environmentally friendly way to dispose of waste. The Asher was then developed and improved until it became a commercially viable unit in 2014. Its patent has been approved in Malaysia, China, Australia and Indonesia, and is being used in a number of other countries, including Malaysia, China, UAE, Indonesia, Singapore, Thailand, Cambodia, Philippines, India and Saint Lucia. The Asher is essentially a tiny waste disposal pyrolysis unit that fits nicely within a typical car parking spot and can reduce most solid waste materials (except glass, metal and concrete) into ash. When waste is put into the Asher, it ends up in the bottom of the thermal degradation chamber, where it will decompose via the plasma pyrolysis process. This is a process of chemically decomposing organic materials at elevated temperaturesin the absence of oxygen. The process involves a change in the materials’ chemical composition, and it is commonly used to convert organic materials into solid residue containing ash, carbon and small quantities of liquids and gases. Tee also designed a water filtration system to filter and suppress the dioxins and furans from being discharged into the atmosphere. The emission generated from the thermal degradation process in the Asher is filtered and cleaned through its combination of liquid and solid filtration media. These media are a patented, specially formulated Nanogreen high-alkaline solution (of 13 types of metallic minerals) and flue gas carbon. Used together, the Asher releases the emission in the form of neutral, non-toxic, non-harmful vapour. The Asher is also equipped with a water self-cleaning system that cleans the liquid used during the filtration system. The integrated cleaning system will clean and alkalinise the contaminated water, which is then reused within the Asher itself.

“It is a very simple operation; the technology is also very simplistic. That’s what attracted us to the Asher – it requires very basic training and supervision for operations and maintenance,” says Thompson.

From trash to ash

WHY IS ASHER THE RIGHT WAY?

- It’s self-sustainable, needing no external energy (2 t solar unit)

- Green, eco-friendly

- Capable of 90% landfill diversion

- Easily mobilised

- User-friendly

- On-site waste management

- Cost-effective