Seven precast concrete reservoirs in the City of Ekurhuleni Metropolitan Municipality (ranging in size between ranging in sizes from 20 Mℓ to 30 Mℓ) are in various stages of completion and form part of the municipality’s water augmentation strategy.

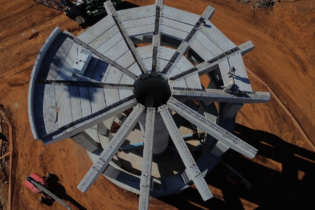

By harnessing prestressed, post-tensioned precast-concrete technology, these reservoirs are completed in record time. A 25 Mℓ reservoir can be constructed in only seven months. This is about half the time that it would take to build a similar-sized reservoir using cast-in-place methods. Significant construction time savings are achieved by enabling the various trades to work simultaneously. The different prefabricated concrete elements that make up the reservoir are manufactured while earthworks and site terracing are underway. They are then integrated on site once the in-situ works have been completed. This includes the footings for the columns that support the centre portion of the roof structure, also referred to as the ‘core’. Once it has been constructed, work on the inner portion of the in-situ concrete slab and ring foundation that supports the prefabricated wall panels can start. Thereafter, the wall panels are integrated on site and the wall post-tensioned via precast-concrete buttresses and placed along the perimeter of the reservoir. By this stage of the construction programme, the reservoir is close to practical completion with only a few outstanding items remaining. Corestruc The municipality’s Water and Sanitation Department have been refining and improving this innovative method of constructing reservoirs since it first deployed the system in 2020. On the first project, Corestruc, a leading precast-concrete specialist, worked alongside Selby Construction, the principal contractor. Tango’s Consultants was the project engineer. The three companies are again working together on the newest 25 Mℓreservoir. “Having worked on a previous project with Selby Construction and many more with Tangos Consulting for the City of Ekurhuleni Metropolitan Municipality, there is already excellent team dynamics between the contracting and engineering teams on site. They know our system well. By now, we’ve learnt many important lessons and have a wealth of knowledge that has made us even more efficient at what we do. This is very evident on this worksite where the build is progressing according to schedule without any major challenges,” Kagiso Maleka, contract manager, Corestruc. As principal contractor, Selby Construction, is supervising the construction of the latest two reservoirs by Corestruc. It also undertook the earthworks and site terracing and is responsible for all in-situ and ancillary works, such as the interconnecting pipework. With the core already in place and a sizeable portion of the in-situ works complete, Corestruc and Selby Construction have started integrating the wall and buttress panels in mid-November. They will work towards completing the project when their teams return from the annual builder’s break in 2024. Quality Corestruc have absolute control over the entire process, starting at its approved factories where the precast concrete elements are manufactured. Working in a factory environment, the company’s concrete technologists can also ensure the perfect dosages of admixtures. This is to achieve early strength development which is crucial for maintaining high levels of production. Just as importantly, a faultless water-to-cement ratio can also be maintained to ensure concrete strength. Aggregates from suitable suppliers are also graded appropriately to avoid early concrete shrinkage. Trial mixes are undertaken for every project to test strength and durability, as well as workability of the construction material. All of the precast-concrete elements are then approved for dispatch to site according to the works programme. This process includes verifying the reinforcement bar size and layout. To ensure the various prefabricated concrete elements comply with the required standards and specifications, quality control checks are also conducted after transportation, another aspect of the precast-concrete value chain over which Corestruc has complete control, and during installation. Roof structures The roof structure comprises precast-concrete columns and beams, as well as hollow-core slabs. Corestruc makes light work of integrating them on site, considering its extensive rigging capabilities. Working closely with the principal contractor, the company oversees the setting out and installation of the column anchors. By confirming the dimensional accuracies before erection, the suspended beams fit the first-time round on top of the columns, reducing delays and waste.The precast-concrete columns are connected to the hold-down bolts in the column basis. Thereafter, the suspended beams are connected to dowels that protrude from the precast-concrete columns. The hollow-core slabs form the roof cover. They are connected to stirrups that protrude from the precast-concrete beams. Steel reinforcing is placed into the voids of the hollow-core slabs which are then filled with in-situ concrete. This forms a composite mechanism that enables the stirrups to work as mechanical interlocks.

Notably, these precast-concrete roof structures are up to five times faster to build than cast-in-place processes. Whereas this is the first to be constructed by Corestruc, the roof is one of the final aspects of the works programme when a reservoir is built using conventional methods. Work on the roof can only commence once the wall and the in-situ concrete columns reach their final height. Many tons of scaffolding must be installed inside the reservoir to support the forms for the frame of the roof structure. The extensive reinforcement and concrete works are also an onerous process that needs to be carefully managed. Then there is the need to coordinate the timely delivery of large amounts of concrete for the continuous pours. In rural areas that are underserviced by ready-mix concrete producers, the construction material will have to batched on site which requires further quality controls. Using permanent locating plates that are fixed to the ring foundation, Corestruc places and positions the wall panels in the same way that it does the precast-concrete roof columns. The first panel is supported by a push-and-pull prop, with the wall temporarily braced back to the roof structure. Steel brackets hold the panels together, thereby, eliminating the need for extensive propping to free up space. Unbonded cables are then pushed through the polyvinyl sleeves in the panels. Thereafter, they are grouted monolithically with the joints of the panels. Walls Then, the wall panels and horizontal cable sleeves are grouted with a high strength and flow grout. It has an extended pot life so that it does not segregate and set to early. This is achieved by manipulating the water-to-cement ratio of 0:37 with admixtures. Water temperature is also reduced and controlled to act as a chiller in the mix. Moreover, only cement, including an un-hydrated type that reacts with water to seal possible leaks, is used in the concrete mix. When the grout has cured to a strength of 80MPa, the cables are stressed to 75%. This is undertaken via six buttress panels that have been spaced along the perimeter of the reservoir. The wall is then pinned by casting a 200mm to 250mm-high reinforced kicker on the wall footing on both sides of each panel. Joints between the panels are grouted with a high-flow and strength grout and post-tensioning renders them in compression to achieve water tightness. Corestruc uses a “slide-and-pinned” system. Post-tensioning is undertaken when the wall is not yet fixed to the ring footing and it is, therefore, allowed to slide on a steel bearing or locating plates. The coated post-tensioned cables are not bonded to the grout with the reservoir designed to maintain a residual compression of a minimum of 1MPa in all directions. Horizontal reactions to the wall base are transferred to the ring foundation through the second phase cast in-situ kicker. Here, the ring tension in the base is also activated to resist the reaction. Additional post-tensioning of the lower part of the wall reduces the amount of rebar required in the cast in-situ ring footing. This is a significantly more efficient and productive way of constructing reservoir walls. Constructing water-tight walls for reservoirs using cast-in-place methods is a complex and specialised undertaking, a task that can only be handled by a few contractors. It entails significant steel-fixing, and the installation of the side shutters is an onerous process. Care also needs to be applied when managing processes such as the placement of the concrete to avoid segregation and the displacement of the reinforcement to ensure a watertight structure. Any mistakes in this aspect of the works programme will require rework and result in costly delays. Flooring As part of the final aspect of Corestruc’s reservoir-construction method, the concrete floor slab is completed and the hollow-core slabs that make up the outer portion of the roof structure connected to the precast-concrete beams. A concrete ring beam is then placed over the hollow-core slabs to form a single monolithic structure and a precast concrete coping installed around the perimeter of the roof as an aesthetic finish. Notably, Corestruc has already helped to deliver 500ML of water-storage capacity using its precast-concrete system. The company was either appointed to construct entire precast-concrete reservoirs or sub-contracted to build the roofs for in-situ structures to reduce construction time and eliminate risk. These projects also stand out as stellar examples of hybrid-concrete construction, with their in-situ walls and precast-concrete roofs. “Corestruc has a strong order book for reservoirs, critical for the supply of reliable source of drinking water to municipal jurisdictions across the country. These projects are located in metropolitan municipalities and smaller districts in rural areas. Certainly, we welcome government’s earlier announcement that it has allocated R14-billion to our municipalities to address water infrastructure backlogs. Some of this money will also be allocated to reservoirs and water towers. We look forward to assisting our clients deliver these projects on time, budget and scope,” concludes Willie de Jager, managing director, Corestruc.