Over the past three decades, bio-trickling odour control has become a proven, reliable solution at wastewater plants. However, despite the technology’s proven track record, there are still many misconceptions or misnomers about bio-trickling filters in the industry that warrants clarification.

A poor understanding of the differences between biological odour control technologies often results in choosing an unsuitable solution for the application. This may result in potentially higher operating cost or disappointing odour removal performance, that leads to biotechnology being labelled as not suitable for municipal odour treatment. The aim of this article is to explain the fundamentals of biological odour control, the elaboration of the various odour control technologies available in the market, and to clear some of the common myths around bio-trickling filters for its suitability to treat municipal odours.Definition of biological odour control technologies

Broadly speaking, biological odour control technology could be divided into three categories:- Biofilters

- Bio-scrubbers, and

- Bio-trickling filters.

Operational differences between bio-trickling filters and bio-scrubbers

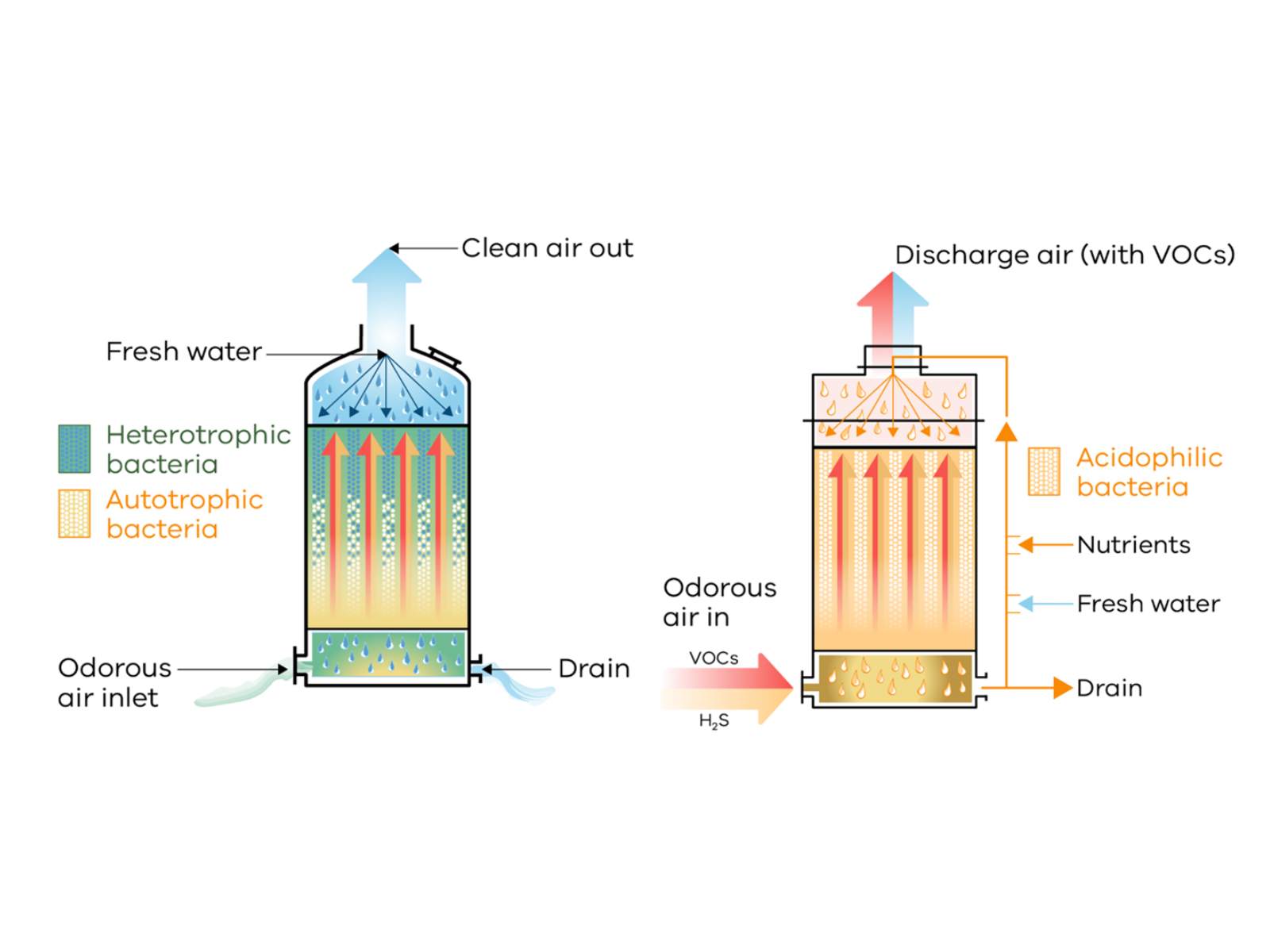

Water is essential for the operation of both bio-trickling filters and bio-scrubbers, since it keeps the biofilm moist and active, and enhances the mass transfer of odorous molecules from the air to the bacteria. Water also removes the by-products of biological oxidization of odorous compounds, in particular sulphuric acid (H2SO4) that is formed during the biological oxidation of H2S to H2SO4 by autotrophic bacteria. The pH of the drain water from either the bio-trickling filter or bio-scrubber is normally controlled at a pH of 2. Bio-scrubbers recirculate the process water in the reactor using a recirculation pump, which is recirculated from either a reservoir in the bottom of the reactor or a separate recirculation sump. This adds to the complexity and maintenance for the system, as well as increasing its energy use. The recirculated water also forms a “thicker” water layer on the media surface due to constant recirculation, which may inhibit mass transfer of the odorous compounds to the bacteria and thus then reduce the odour removal performance of bio-scrubbers. Bio-trickling filters operate in a “once through” manner whereby the irrigation water enters the media pack at the top and “trickles” down to the bottom media layers after which the liquid is removed directly via drain at the reactor bottom. Bio-trickling filters do not recirculate water. Due to the “once through” irrigation method, neutral pH water enters the top media pack and trickles through the packing media while absorbing H2SO4 and other by-products of bacterial oxidation from the reactor. This irrigation method also results in a “thinner” water film on the media surface, which improves the mass transfer of pollutants from the air to the bacteria, which is especially important for pollutants with low water solubility.

Figure 1 illustrates the operating principles of bio-trickling filters (left) and bio-scrubbers (right) Credit: Environmental Protection Authority, Victoria

Understanding the microbiology associated with municipal odour removal

Municipal odours mostly consist of a mixture of H2S, ammonia (NH3) and ROSC. ROSC includes compounds such as mercaptans, dimethyl sulphide, dimethyl disulfide and carbon disulfide. All these compounds have very low odour detection threshold concentrations and thus must be treated to very low concentrations to avoid any odour nuisance concerns.

In bio-trickling filters and bio-scrubbers, H2S is removed by autotrophic bacteria. Autotrophic bacteria obtain its carbon for microbial cell synthesis from the carbon dioxide (CO2) in the air. These bacteria can grow under both acidic and neutral pH conditions.

In bio-trickling filters, ROSC is removed by heterotrophic bacteria that grow optimally under neutral pH conditions. Heterotrophic bacteria obtain the carbon for microbial cell synthesis from the carbon in the ROSC molecules.

A unique difference between bio-trickling filters and bio-scrubbers is that bio-trickling filters allows the growth of both autotrophic bacteria and heterotrophic bacteria, and thus bio-trickling filters can remove both H2S and ROSC in a single reactor vessel. Bio-scrubbers on the other hand, allows the growth of autotrophic bacteria only and thus removes H2S only.

The ability of bio-trickling filters to allow for both autotrophic and heterotrophic bacteria to grow in a single reactor vessel allows for treatment of a broad range of odour compounds in municipal airstreams.

Municipal odours mostly consist of a mixture of H2S, ammonia (NH3) and ROSC. ROSC includes compounds such as mercaptans, dimethyl sulphide, dimethyl disulfide and carbon disulfide. All these compounds have very low odour detection threshold concentrations and thus must be treated to very low concentrations to avoid any odour nuisance concerns.

In bio-trickling filters and bio-scrubbers, H2S is removed by autotrophic bacteria. Autotrophic bacteria obtain its carbon for microbial cell synthesis from the carbon dioxide (CO2) in the air. These bacteria can grow under both acidic and neutral pH conditions.

In bio-trickling filters, ROSC is removed by heterotrophic bacteria that grow optimally under neutral pH conditions. Heterotrophic bacteria obtain the carbon for microbial cell synthesis from the carbon in the ROSC molecules.

A unique difference between bio-trickling filters and bio-scrubbers is that bio-trickling filters allows the growth of both autotrophic bacteria and heterotrophic bacteria, and thus bio-trickling filters can remove both H2S and ROSC in a single reactor vessel. Bio-scrubbers on the other hand, allows the growth of autotrophic bacteria only and thus removes H2S only.

The ability of bio-trickling filters to allow for both autotrophic and heterotrophic bacteria to grow in a single reactor vessel allows for treatment of a broad range of odour compounds in municipal airstreams.

Common myths associated with bio-trickling filters

Although bio-trickling filter technology has been widely studied over the past decades, several misconceptions still exist and biasedly influence the technology selection as it pertains to municipal odour control. Here are some of the most common myths:- “Bio-trickling filters are only suitable for hydrogen sulphide removal.” As explained herein, bio-trickling filters are suitable to be used for treatment of a wide spectrum of municipal odour applications, i.e. from headworks with H₂S and low ROSC concentrations to sludge treatment with higher NH3 and ROSC concentrations. Bio-trickling filters’ ability to host both autotrophic and heterotrophic bacteria allows it to handle a mix of organic and inorganic odours in a single reactor vessel, thus reducing its footprint requirements and eliminate the need for secondary polishing.

- “Biotrickling filters require carbon polishing to remove ROSC compounds to meet stringent air quality standards.” While true for bio-scrubbers, bio-trickling filters can achieve sufficiently low outlet odour concentrations that meet most odour treatment requirements without the use of carbon polishing. The combination of a diverse microflora, i.e. autotrophic and heterotrophic bacteria in the same reactor, along with favourable mass transfer conditions are sufficient to meet stringent air quality targets. Bio-scrubbers, on the other hand, almost always require a second stage carbon polishing or biofilter to achieve acceptable odour removal.

- “Bio-trickling filter units use more water that bio-scrubbers which make them less suitable for water scarce applications.” Water use requirements for both bio-trickling filter and bio-scrubber systems use the same when operated at the same drain pH conditions. Both technologies require low water usage.

- “Bio-scrubbers that use random PUF media provide the same level of H2S treatment performance as bio-trickling filters that use structured synthetic media for a given empty bed residence time (EBRT).” False. Structured media generally supports better gas flow, more uniform irrigation, and improved mass transfer. This means a bio-trickling filter with structured media can achieve the same removal efficiency in a much shorter empty bed residence time (EBRT) compared to one using random media – often at a third (33%) of the EBRT than a comparable bio-scrubber.

Bio-trickling filters – a practical choice for municipal odour control

In the author’s experience, a well-designed bio-trickling filter offers an adaptable, dependable and sustainable solution for municipal odour control and management. It can be applied effectively to almost any stage of a wastewater treatment works – from the initial headworks to sludge handling areas – as well as in pumping stations and sections of the sewer network where odour complaints are present.

Annejan Visser, professional engineer (chemical), Zutari