Paul Warrener, development and marketing manager at Rainbow Reservoirs

“From the outset, our goal was to design tanks that meet the Australian water industry standards, which are among the strictest globally,” Warrener explained. “Even though we operate locally, we have always aspired to match international benchmarks.”

Materials and durability

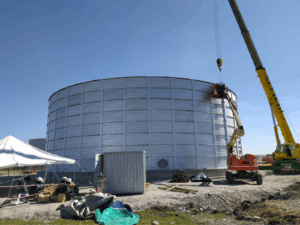

The key to meeting client expectations is “ensuring that standards are met and exceeded. We manufacture to Australian standards because they are highly regarded and allow us to have a global footprint.” Part of these standards is a careful selection of materials. Rainbow Reservoirs manufactures its tanks using Aluzinc steel and RPVC liners, both chosen for strength and corrosion resistance. According to Warrener, Aluzinc comprises 55% aluminium, 43.4% zinc and 1.6% silicon, making it “around six times more resistant to corrosion than standard galvanised steel”. It is also heat- and thermo-resistant, extending the lifespan of each tank. The company’s tanks are designed with a 40-year life expectancy, provided that installation and site preparation are completed to specification. “Smaller tanks don’t even require concrete bases,” Warrener said. “They can be installed on compacted ground with a plaster-sand layer, which reduces cost for smaller clients.” The tanks comprise the shell and the liner; there is no bottom, so while site preparation is essential, the tanks are also easier and less time-consuming to place than tanks requiring a bottom shell. While international standards apply, the company also ensures South African National Standards (SANS) compliance. Engineering calculations incorporate safety factors for hydrostatic pressure, wind loading and thermal expansion. “The design combines high-quality materials with proven installation and construction methods,” Warrener says. “This ensures the tanks remain reliable, durable and fully functional in demanding environments.”Modular engineering

Rainbow Reservoir tanks come with a 12 year warranty and are built to last 40 years

“If a panel needs to be replaced, it can simply be removed and substituted without affecting the rest of the structure,” he adds. “Downtime is minimal.” On larger tanks a manhole is fitted, which means that leaks are easier to isolate and repair.The modular nature of the tanks means customisation and context-specific tanks are easily pulled together. Warrener cites a project at the Mall of Africa, where two nine-metre tanks were installed within a confined parking structure. “The spiral elevations that drive up a level have a column in the middle. We were able to install the tanks on-site in this space precisely because of the modular design. An approach that would have been impossible with welded tanks,” explains Warrener.

Application in mining

Rainbow Reservoirs’ modular tanks are increasingly used in mining applications, where they must withstand corrosive and high-stress environments. “Our materials and coatings are designed to handle aggressive water chemistries associated with mines,” says Warrener. “Alongside Aluzinc, the Components are hot-dip galvanised, and for highly corrosive conditions we use fusion-bonded epoxy (FBE) or thermoplastic powder coatings.” The liner materials are selected based on the type of liquid being stored. “We adapt the liner’s composition and thickness depending on the water’s acidity or intended use,” he adds, “for daily use like showering and cleaning, the liners will differ from those in operations.” The integration of tanks within a mine’s water management system requires detailed engineering consideration. “Water balance is critical,” notes Warrener. “The tank’s capacity must align with the mine’s operational demand, and the inlet and outlet systems must support process efficiency. Every installation is assessed for scalability and sustainability.” Rainbow Reservoirs ensures compliance with all site-specific safety standards during installation. Once commissioned, operational monitoring is managed by the client. “After commissioning, the mine assumes responsibility,” says Warrener. “However, we provide full after-sales support. Our tanks carry a 12-year warranty and are designed to last approximately 40 years.”Global reach

Transporting the tanks is relatively easy as they are flat packed as opposed to fully assembled

“The first phase, completed earlier, provided 12 million litres of storage, sufficient for 72 hours of backup supply. This year, we expanded capacity by an additional 22 million litres with four 5.5-million-litre tanks, each approximately 28 metres in diameter.”Reflecting on the company’s long-term performance, Warrener described a field visit to one of Rainbow Reservoir’s earliest installations. “I visited a small farm tank installed over 14 years ago,” he said. “Apart from consumables such as bolts and the liner, the panels and structure were still intact. It reinforced my confidence in the durability of our materials and design.” Rainbow Reservoirs’ approach demonstrates how modular engineering can deliver robust, scalable, and cost-effective water infrastructure across multiple sectors. Through its focus on material quality, standard compliance, and adaptable design, the company continues to position itself as a leader in sustainable water storage solutions.