The rapid rise in the global population, coinciding with the manufacturing, mining, processing and demand for consumer goods, has placed additional pressure on waste management.

Whilst there is an ongoing effort to divert waste, both municipal and industrial, through policy, guidelines, stakeholder engagement by government, sustainable development goals (SDGS), environmental, social, and governance (ESG) indicators, and a general push towards sustainability, there are still fundamental gaps that need addressing. Adding to this growing gap in recycling improvement is the advent of technology and digital products, creating another recycling challenge of its own. Among all the waste streams, e-waste stands out as one of the fastest-growing and most problematic due to its hazardous nature and recycling challenges. With electronic waste recycling, the following aspects can hinder recycling and effectively be barriers:- Complex composition of materials – you find motherboards are glued together, making it difficult to separate recyclable parts

- Some materials like Cadmium, Mercury, and PFAS (Polyfluoroalkyl substances, a group of synthetic chemicals having resistance to heat, oil and water) in some coatings pose a challenge for separation and re-use.

- The complexity of some hazardous materials means that the research and development of new technology to treat such materials can be very expensive and could require numerous steps before being able to be recycled or reused.

- The competitive push to develop the best products means there is a continuous drive to have the leading technology out in various products; however, little thought is given to the “end of life” management of these products. This creates the burden of building stockpiles of used products with electronic components where no recyclable solutions are commercially available. This links directly to the Extended Producer Responsibility (EPR), and this is largely lacking and fragmented, as mainstream manufacturers of these products are situated in various parts of the world where compliance and commitment to recycling are variable.

- The economics of recycling can easily outdo the costs of manufacturing an electronic component in a product. The investment costs in recycling may not prove to be feasible for the producer.

- The lack of awareness and education towards promoting recycling and re-use of materials is a fundamental problem across the entire value chain of e-waste. As shown in Fig. 1, there is an opportunity to create education and awareness in the recycling chain.

Looking at it together, these barriers illustrate why global e-waste recycling rates remain stubbornly low despite advances in sustainability frameworks.

Further to this, it is also worth noting the socio-economic and environmental dimensions in the recycling of e-waste:

Looking at it together, these barriers illustrate why global e-waste recycling rates remain stubbornly low despite advances in sustainability frameworks.

Further to this, it is also worth noting the socio-economic and environmental dimensions in the recycling of e-waste:

- Human health: Informal sector workers (often children and women) are heavily exposed to toxins from manual dismantling, open burning, and acid leaching.

- Economic shrinkage/loss: The lost value of raw materials in e-waste (gold, rare earths, copper, palladium) is huge. The Global E-waste Monitor estimates this to be over USD 60 billion annually.

- Environmental persistence: Hazardous additives like brominated flame retardants, PFAS, and heavy metals not only affect soil and water but also accumulate in ecosystems and food chains.

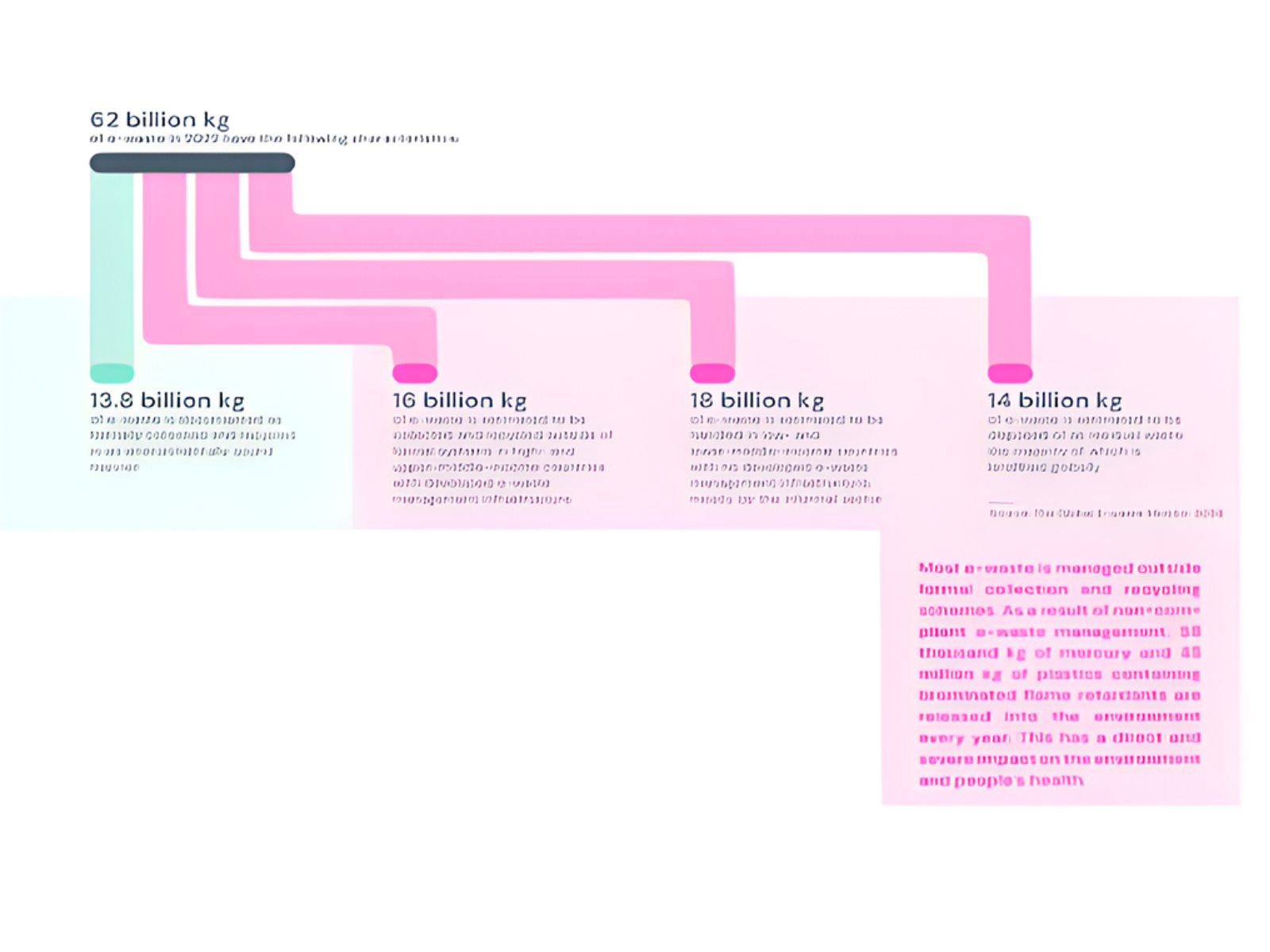

As per the global e-waste monitor 2024, the data shows that in 2022 outlined the breakdown of characteristics of e-waste in the formal and informal sectors in Fig. 2. Interestingly, the estimates still show that 14 billion kg is disposed of as residual waste in landfills. These statistics indicate an estimated 22,3% of e-waste was formally collected and recycled.

Opportunities and solutions for improving e-waste recycling

To meet the e-waste barriers:- Manufacturers should focus on design for the end of life of electronic components. With this focus, they follow a circular approach towards effective product stewardship and recycling.

- As a producer, develop a common thread approach towards extended producer responsibility globally, you follow the relevant policies across the various countries, but also ensure that you demonstrate a commitment towards EPR.

- Establish strategic relationships with innovation hubs, technology manufacturers, eg, Plastic recycling, metal recycling, specialised technology suppliers like pyrolysis and others.

- Working closely with the informal sector to educate them further on how to work better with electronic components and products to reduce risks, improve working conditions, especially around health impacts and environmental contamination.

- Active awareness campaigns with consumers to get them to learn and practice how to dispose of and recycle electronic components safely.

Complex components make e-waste recycling difficult and labour-intensive

Neeraj Mannie, strategic infrastructure and sustainability executive