Hugh Khumalo, national Haztech and

inland southern commercial manager,

EnviroServ

“Sludges are managed and transported using a range of methods. In some cases, sealed tankers are used instead of tippers, and additional treatment processes – such as odour-control measures – may be required, with certain sludges ultimately needing incineration,” explains Khumalo.Before any treatment or disposal route is considered, EnviroServ conducts a detailed assessment through its accredited laboratory working alongside the company’s alternatives team and hazmat specialists. Samples are analysed to determine whether sludge should be stabilised, dewatered, incinerated or landfilled. “These departments work together to determine the safest and most responsible solution before any proposal is presented to a customer,” says Khumalo. EnviroServ uses several treatment technologies depending on the classification of the sludge and prevailing legislation. Treatment at EnviroServ’s Holfontein Waste Management Facility range from ash blending to more technical applications using lime, ferro-sulphate or specialist stabilisers for difficult waste streams. Wherever possible, alternatives to landfill are prioritised. Holfontein is South Africa’s largest hazardous waste management facility. It is engineered to safely take Type 1 to Type 4 wastes, and is equipped with treatment processes capable of treating even Type 0 materials before disposal.

Dewatering

Transporting sludge carries inherent risks. EnviroServ selects sealed tankers or RoRo bullet tankers where necessary and uses advanced digital systems for route planning, manifest control and compliance with UN/TREM requirements. These UN-aligned Transport Emergency (TREM) protocols ensure that drivers have the hazard information and emergency actions needed to move dangerous goods safely and transparently.

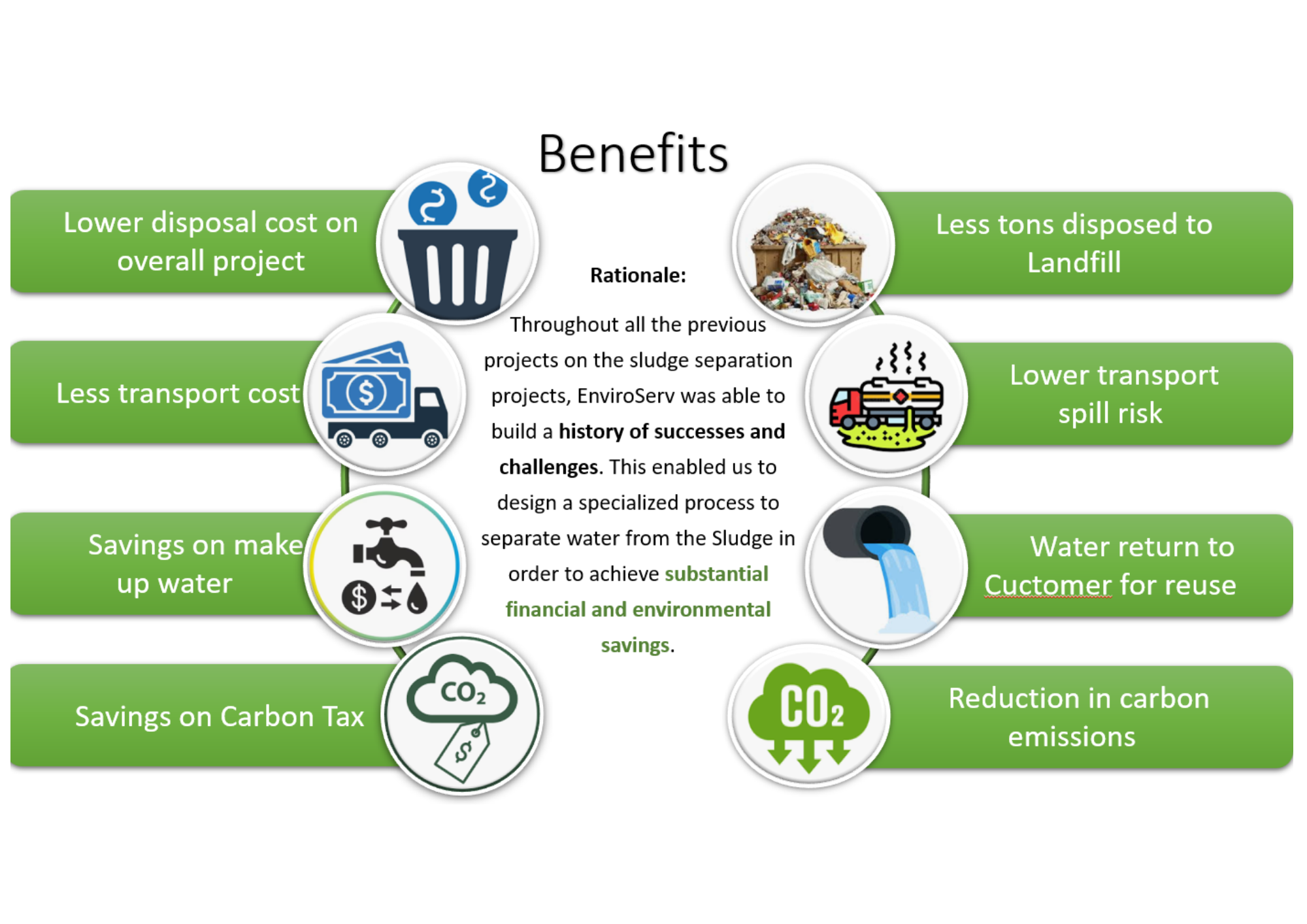

Transporting sludge carries inherent risks. EnviroServ selects sealed tankers or RoRo bullet tankers where necessary and uses advanced digital systems for route planning, manifest control and compliance with UN/TREM requirements. These UN-aligned Transport Emergency (TREM) protocols ensure that drivers have the hazard information and emergency actions needed to move dangerous goods safely and transparently.A major focus area in recent years has been reducing the transport and disposal of water-rich sludge. EnviroServ has developed a sludge dewatering system in partnership with a specialist supplier. This system extracts sludge from dams, dewaters it, and returns low-solids water to the client’s process.

“This approach significantly reduces the number of trucks on national roads, lowers carbon emissions and ensures that prohibited liquid wastes do not reach landfill,” notes Khumalo.In one project, belt presses were used to extract sewage sludge from an overloaded treatment dam, helping the client restore capacity and avoid compliance issues.

Transporting sludge carries inherent risks, thus a reliable and compliant supplier is required

Treated sewage sludge from water treatment plants may be used as lawn-dressing material